Sliding windows are a modern glazing method, which is increasingly gaining popularity. Use sliding structures on the verandas, balconies, in the arbors and between the rooms. To establish such a system with your own hands will not be difficult, you only need to choose a suitable opening mechanism and the material from which the profile will be made.

Content

- Advantages of sliding windows

- Types of opening mechanisms for sliding windows

- Types of profiles for sliding windows

- Installing sliding windows PVC do it yourself

- Installation of aluminum sliding windows with your own hands

- Installation of frameless glazing with their own hands

- Important Tips for Operating Sliding Window

- Installation of sliding windows: video

Advantages of sliding windows

So, the sliding windows are much more convenient to us habitual:

- it is possible to rationally use the entire area of \u200b\u200bthe window sill: you do not have to remove the vases with flowers or decor items to open the aircraft to air;

- curtains and blinds are not deformed, and, most importantly, do not interfere with opening the sliding window;

- open sliding windows are securely fixed, therefore there is no risk that the sash flashes the draft;

- sliding windows can be installed on the floor to the ceiling;

- the narrow frames of sliding windows do not close the light, in addition, a wonderful panoramic view from the window will not be corrupted by a plurality of window jumpers;

- the design may easily be installed on remote balconies;

- sliding structures allow you to create unusual interiors.

Types of opening mechanisms for sliding windows

Sliding windows are cold and warm: if there is heating on the veranda (terrace, balcony), then it is advisable to use hermetic systems so that the room can be operated all year round. Also, when choosing a design, it is important to take into account the area of \u200b\u200bthe glazed surface: not all sliding structures can withstand too large glass or approach floor-to-ceiling. Although the cost of conventional swing windows is lower, but sliding justify their price functionality.

Depends the price of the sliding system from:

- glazing area;

- type of construction;

- material from which frames are made;

- quality of fittings (the price of the same detail in different manufacturers can differ in principle);

- tinting or decorating windows (if it is assumed);

- the quality of the mosquito net;

- will you carry out installation yourself or invite specialists.

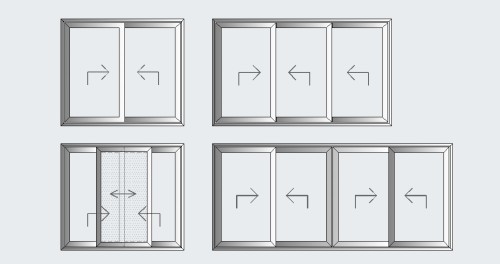

Lifting-sliding design

The principle of the mechanism is similar to the principle of doors in the wardrobes. When you open the window, slightly lifting it, weakens the clamp of the sash below, and the frame is easily shifted to the side (on the width of the adjacent frame). And when you close the window, the mechanism presses it from below, so that the seals closed, and the frame got into place. At the same time, the rubber seal makes the design completely sealed: it isolates the heat, and also perfectly copes with the function of waterproofing the room.

Accordingly, the entire design should consist of at least two frames: carrier and movable. At the same time, the guides for moving frames (one or two), as well as for a mosquito net, which can be shifted to the carrier part of the design.

The lifting-sliding design has sufficient strength and stability to withstand the sash of the maximum size (2x3 m). It is with the help of such systems interior designers create so-called sliding walls between rooms in the house or between a residential premises and the street. In the country house, invisible glass walls will create the effect of unity of the living room with a garden or bedroom with a terrace, while ensuring a reliable barrier from the penetration of cold air, moisture or insects at any time of the year.

Made lifting and sliding design can be from PVC or aluminum profile. At the same time, if you decide to install such windows in the entire height of the room, the threshold is made smooth and barely noticeable - it does not share spaces and does not create difficulties in caring for a sliding system.

PVC-sliding design

Such a window system is very similar to the device on the ordinary PVC swing window. But when opening the frame, its movement goes along two guides that are fixed on the carrier frame (the doors in the "Ikarus" bus operate on the same principle). To open the window, you need to pull the sash on yourself (the rollers will be installed in the end), and then move the distance you need and fix it. For fixing, the handle of the clamping mechanism is rotated. The fittings of the sliding frames of this type are the same as the usual swing plastic windows, so the frame can be opened on the ventilation. A similar and sealing, so moisture-, heat and noise insulation will be at the same high level.

Such a system of sliding windows is perfect for glazing balconies or veranda - from the railing to the ceiling. Its installation will save the space of a small residential premises. Significantly less frequently sliding system is used to create structures in the entire height of the room (for example, to exit the terrace). The fact is that the PVC frame is not intended for use as a threshold - the design can be disturbed from permanent advancing on it. If for some reason you still decide to use this system for the equipment of the sliding door, ask the manufacturer with special overlays on the threshold that will help extend the life of the PVC design.

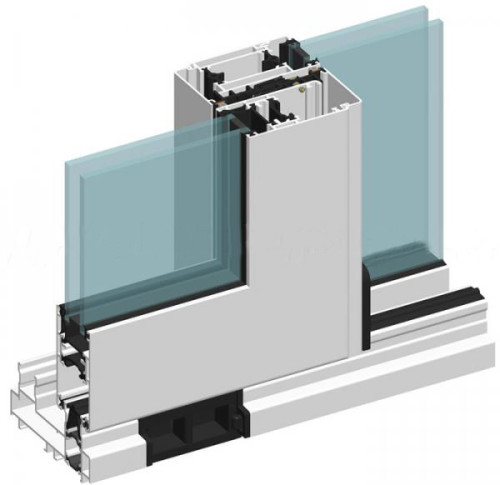

Sliding aluminum system

This design refers to the category of "cold" - that is, unable to fully maintain heat indoors. That is why aluminum systems are used inside the house or for glazing the veranda or balconies. But as a partition between the residential room and the street they are not suitable.

Aluminum system is rigid and durable: allows you to create large glazing areas (including floor to ceiling) without jumpers. In addition, the metal frame itself looks almost weightless compared to PVC and does not distract attention.

The principle of functioning of the structure is based on the fact that the sash moves along the guides parallel to each other. Polymer coating rollers provide silent and smooth motion with such windows. In the closed position, the frame is securely fixed by a special lock.

Shift folding system

In the people, such a mechanism is called "Garmoshka". The design consisting of several shutters, which are interconnected, when opening, fold as a fur of harmony.

The "Harmonica" system can be used to maximize space saving: it opens to the entire width of the opening and does not need an area to displace the system.

The design can be made both from PVC and from the aluminum profile. The latter is used much more often: it is easier, but at the same time withstands heavy loads.

The "harmonica" can be installed in the opening of up to 6.5 m in width and 2, 3 m in height. In this case, the number of sash should not exceed seven pieces.

Frameless glazing

For the design of the terraces, the veranda and other open areas, a frameless glazing system is very often used. In the closed state, the construction is a solid glass wall that is not divided by racks or frames. Glass blocks move along a special guide installed in the upper and lower part of the opening. Space can be completely discovered by shifting all the sections in one direction, where they are collaborated like a book.

Designers very often offer their customers just such a system to create a fully open space effect. In addition, the design has undoubted aesthetic advantages, it is also quite functional:

- in open state does not occupy space;

- very smoothly and gently opens;

- made of special kaneylene glass, so resistant to mechanical damage and safe to use;

- glass is very easy to wash - there is access to both sides of the surface.

Types of profiles for sliding windows

PVC profiles. These are the most practical and warm systems. In the frame you can insert 1 or 2 windows - they will reliably protect against dust, noise, water, strangers and penetration of cold air. Very easy to use and mosquito nets for such designs.

PVC as material has a number of undoubted advantages:

- easy to wash;

- shockproof;

- resistant to extreme temperatures (for example, in winter the frame does not face);

- not deformed over time;

- durable;

- the emergence of draftsman;

- accessories during operation, if necessary, will be easily replaced with a new one;

- acceptable cost;

- assortment of colors (except for the traditional white you can, for example, order also frames under the tree);

- expansion of functions (there is the possibility of remote control of windows by means of a console or installation of an additional protection system against hacking from the outside).

As for the shortcomings, it is primarily worth mentioning the weight of the structure. It is because of the high weight PVC has limitations on the width of the sash, as well as in the height of the design.

Aluminum profile. This light and elegant system is used for glazing summer terraces, country veranda and decorative arbors. But if you have the task of creating a room for operation in winter, including, then most of the range of aluminum frames will not fit you - the temperature in the room will be close to the temperature on the street (double-glazed windows in such frames are not installed - only ordinary glass).

Among the main advantages:

- reliable protection against dust and dirt;

- the design is durable and easy (gives a small load on the walls);

- withstands strong gusts of wind;

- frames are narrow, so they give the possibility of a wide review;

- metal is not subject to corrosion;

- for aluminum windows it is easy to care for the fact that the alloy pushes dust and dirt (it is enough to wipe them simply with a wet cloth);

- will last you for more than 50 years;

- the sash area can be very large (including for glazing from floor to ceiling);

- although the natural color of aluminum is gray, the frames can be painted in production in various colors.

There are completely sealed structures from aluminum, but their price is very high - they do not use popular among consumers precisely for this reason.

Installing sliding windows PVC do it yourself

- Plastic systems of sliding windows have carriers ("deaf") frames.

- The upper and lower parts of the window span are equipped with a profile (lining), and the so-called mounting mustache is fixed to it.

- The "deaf" frame is inserted into the window opening, where it is fixed with self-draws from all sides.

- Next, all frames connect with a threaded screed.

- If PVC packets are installed in the entire height of the room, then to strengthen the design, the racks for the concrete base are mounted.

- When the installation is over, plugs are installed in the openings in the profile, and the gaps between the window and walls are placed by mounting foam.

- Next occurs the fastening of the directional-sliding system, and the flaps are mounted on the end of the "deaf" frame.

- To install the sash, it is entered on the upper guide, compare, and then lowered to the bottom.

- During the installation, it is very important to establish frames strictly horizontal levels, otherwise the sash splenning system will be broken.

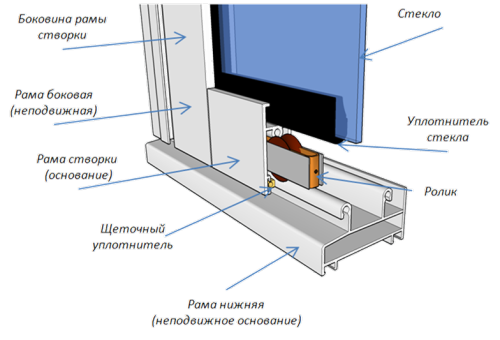

Installation of aluminum sliding windows with your own hands

For self-installing aluminum sliding windows, you will need: hammer, chisel, level, mounting foam, drill.

- We open the windows before installing the windows you need to thoroughly align.

- The frame is exhibited strictly horizontally (according to the level) and fixed with anchors.

- When the frames are installed, the space is sealing between the profile and the wall. To do this, use the mounting foam.

- After the assembly of the main structure is completed, it is possible to install sliding windows and fittings.

- At the bottom of the flap, the rollers are fixed (2-3 pieces).

- On the ends of the sash, the brush seal is mounted (it is he who prevents the penetration into the dust, and also helps reduce the noise level).

- After the sash is prepared to be installed in the end: first get to the upper guide, and then lowered to the bottom.

- The final is carried out in the installation of the window sill (if it is provided for design).

Installation of frameless glazing with their own hands

We make such structures on individual measurements. If the measurements are removed correctly - this will mean almost complete absence of gaps between the design sections.

- The upper profile is fixed with anchors or rivets. In the process, the horizontal position of the profile is measured using a level, and plates (metal or plastic) are used to adjust the position. When the position of the design is strictly horizontally, it is fixed to the base.

- Then the bottom profile is fixed. At the same time, the distance from the upper to the lower profile should exactly correspond to the height of the frameless sash.

- Glasses are installed in order. Side flaps (lamella) are equipped with a seal.

- To the guide glasses are fixed by loops and move on the place.

- When all glasses are installed, mount fixing and adjusting accessories.

Important Tips for Operating Sliding Window

- Once a few years, it is recommended to remove the sash and conduct a capital cleaning of the vacuum cleaner of all elements of the design from the accumulated dust.

- If you installed aluminum windows, their brush seals need to be cleaned at least once a year.

- Windows with a lifting and sliding mechanism into severe frosts can stop opening, but this does not mean that the mechanism is damaged. Do not attempt to open the window, applying force, use a special defrostor or just warm air dryer.

Start a discussion ...

Start a discussion ...