Among the enormous variety of materials that are used for finishing works, the stone occupies a leading position, because it can be used not only for internal, but also for external work. The facade finish of the stone does not lose its relevance for many years, since it is practical and aesthetically. Naturally, the design of facades with a stone is to trust only professionals, because to make this work personally, without the necessary experience and knowledge is not easy. In confirmation of this, we will tell you how to separate the facades with a stone in the most detailed as possible.

Facing facade stone: benefits

Despite the widest range of materials, architects, designers and builders prefer to cover the facade of the stone, because only such a coating allows you to significantly extend the life of the external walls of the building, as well as to make it original and aesthetically more attractive.

Consider the advantages that the facade facing natural stone has:

- Diversity.

In the modern market, not only all sorts of types of stones are presented, but also various forms of release. Facing facing stone can be carried out with tiles, limestone strips and even whole stone slabs.

- Original appearance.

In addition to the fact that the stone for the facade has the unsurpassed beauty of natural patterns and textures, each of them is unique in its own way. Thus, the facade cladding in such a material of various forms and shades will definitely allocate your home among the neighboring buildings. Regardless of whether the facade is linked completely or only some part of it, it will always look spectacular and original.

- Practicality.

It is well known that the stone has high practical indicators. He is not afraid of a high level of moisture, no temperature drops. It does not fade in the sun and is little subject to mechanical damage. An important factor is that the laying of stone on the facade will significantly extend the life of the most building, because it will help protect the walls from various negative impacts for many years.

- Efficiency.

Natural stone is quite expensive, however, the trim of the facade with a decorative substitute its substitute has all the advantages of the source material, but it is much cheaper. Of course, the natural stone looks much more interesting to artificial analogues, nevertheless, in closest consideration, few people can distinguish it from the original.

Materials for finishing facades

An unusually decorated facade of any building is attracted and attracts a lot more attention to him than a boring panel house. Sooner or later, the owner of the mansion thinks about the finishing of his house with a presentable facing coating. The materials used for facing work will not only decorate and give the house a unique appearance, but also protect the walls from external influences that destroy the building, as well as increase its thermal insulation.

Facing materials: types

Building stores offering consumables from their buyer have a huge range of various products. All variety of facing tiles can be divided into a group of natural and artificial stone.

Natural facing stone

- The group of natural facing material includes: quartzit, granite, basalt and marble. All these natural stones are characterized by high hardness, durability, reliability, resistance to climatic influences and durability.

- Houses lined with such materials look luxuriously, but natural stone itself is heavy and requires additional strengthening of the foundation.

- Granite and marble almost do not differ in their physical and technical characteristics. Marble has a greater choice of textures and amazing, very rich color scheme. As a building material, it is more aesthetic and easy to work.

- Black and red granite is no less monumental, but it is much cheaper and more often used as facing material buildings around the world. As a rule, this material is used when coating the heads of administrative buildings.

- The most inexpensive material in this group is a slate. This is a layered material that is easily divided into plates. It has high aesthetic qualities, as well as easy, which allows it to be used not only for external cladding of buildings, but also for intricate work.

- Cheaper and light natural stones are limestone, slate and sandstone. They are widely used for cladding of facades of private houses of a budgetary nature.

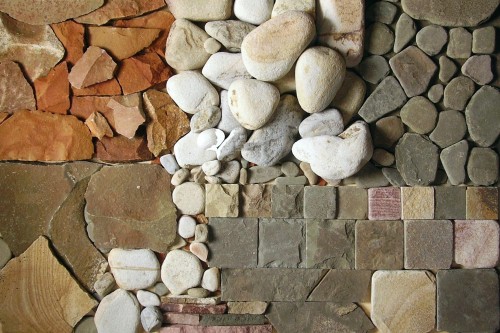

- Another practical natural material for the facing of the external walls of the house is the Dagestan stone. It is completely environmentally friendly, it has a high degree of safety and serves as a good heat insulator. Dagestan stone is usually sold white or gray colors, although shades can be more diverse. The formation of the structure of the wild stone occurs when the climatic conditions are influenced in the places of its formation.

- Wild stone is two species: the shell and sandstone. Accordingly, they have a different chemical composition and properties of the finished material. It is these types of natural wild stones that are most practical to finish the facades of houses. As a result, the wall acquires the original drawing and a variety of composite solutions.

- Houses decorated with wild stones are comfortable for living: in the summer they are cool in them, and in winter it is warm. In addition, it is used not only for facing works, but also for the manufacture of various architectural elements: railings, arches, and sometimes columns. Such natural stone is easy to process both with the help of stone machines, and manually, which is very important when independent facing.

- Natural materials are distinguished by unique natural beauty. Special love of designers and architects enjoys marble.

- Facade facing also often use natural clinker tiles. This is a clay that has passed high temperature processing. Having melted, it turns into a tile with very high frost resistance, strength and resistance to the effects of ultraviolet radiation, in other words, it does not fade in the sun. Such a tile is realistic imitates the brick and serves for many years.

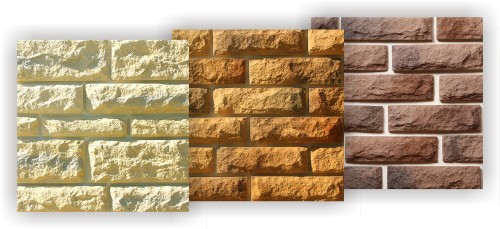

Artificial or decorative stone

- The design of facades of houses with decorative stone is very popular. In the facing material market, artificial stone is represented by a large variety of colors and textures. The cost of artificial material is significantly lower than natural, it is much easier and easier to work with it.

- There are many ways to manufacture artificial facing material, the most common of them is the technology called "vibrating". The mixture consisting of mineral aggregate, dye, cement or acrylic resin is poured into a special form. After that, the form is placed in the vibrostank. Content, vibrating, fills the outer side of the stone, providing it with the necessary density.

- Artificial or decorative material in their physical properties is no worse than natural, but for some indicators even better. Durability, durability and stability This material is not inferior to a natural fellow, and in weight it is much easier, and therefore the need for additional costs to strengthen the foundation.

- The material created by man has an increased resistance to erasure and is characterized by good impact resistance. In addition, the mold is never formed on the surface of an artificial stone, and the process of facing work does not require large labor costs.

Where to buy facing material?

You can buy facing material in online stores or building supermarkets. In addition, there are specialized organizations providing services for finishing the facade stone. The range of the proposed samples is very diverse. In supermarkets, you can feel samples of goods, and in online stores to explore photos, technology and structure of facing materials.

Facade design

- When finishing the wall at all, it is not necessary to cover the entire wall with a stone. Very original look at home with combined use of plaster and stone. As a rule, the plaster is covered with the upper part of the walls, and the windows, doors, base and corners of the house are framed by stone. Gentle, bright shades of color plaster contrast with cold colors of facing stone and create an unexpectedly attractive design. 2. For the integrity of the style, the local area is drawn up with the same material - decorate gazebos, fence and tracks.

- Often designers break the facade to vertical and horizontal zones. Combining different materials in zones, the rhythmic motifs of the facade are obtained.

- Sometimes there is a combination of more than two materials for the external design of the walls, up to decorative plaster under the stone and design of the base of various types of stone.

Facade Finish Stone: Step-by-step instructions

Calculation of the number of material

The process of facing the facade of the house by stone provides for a number of works with a clear sequence. After the design project, the design of the facade of the house is drawn, it is necessary to calculate the amount of consumable material for its incarnation.

- the material intended for the facing of flat surfaces is calculated on m²;

- the calculation is reduced to the definition of the total flat area of \u200b\u200bthe facade and is divided into one unit of material;

- for angular parts, it is necessary to summarize the length of all external corners and divided into the length of the material, adding 10% of the safety for the needs of additional consumables under the features of each facade.

Preparation of walls to facing

- The condition of the facade has an important value for high-quality work on its facing. For wooden and plasterboard walls, the humidity indicator should not exceed 0.5%, and for cement - is within 4.5%.

- The outer wall of the facade should be smooth, the permissible drop is not more than 2 cm per m². The strength of the walls, which, after cladding, will experience an additional load, should be determined by the figure of 1-1.2.2 MPa. It is important to exclude the potential deformation and shrinkage of the facade. For this purpose, all the remnants of previous facing, any finish, insulation, paint and oil should be eliminated.

- If the state of the outside of the building meets all the above requirements, you can proceed to the preparation of the surface for the facing. Specialists are recommended to start with the imposition of an insulating layer. Usually, parchment or rubberoid is used for this.

- Then the walls are fixed with a galvanized metal grid for future plaster. On top of it, 2 cm layer of plaster are applied. The surface of this layer is thoroughly aligned.

- It is important to finish with a stone to start at air temperature from 6 C to 25 C.

Registration of facade stone

- If the start of facing works coincided with high temperature indicators, it is important to moisten the walls before entering. To do this, you can use the usual brush or the water sprayer.

- Then the craftscher evenly cover the purned side, pre-prepared parts of the facing, solution. After that, with an effort pressed the item to the wall so that the solution spoke from all sides. Carefully removing excess, leave a thin layer of the fastening mixture on the surface of the stone.

- After laying all the details of the facing, there comes a turn of the joints of the seams. So that the seams are neat, use special tools to align them. The simplest tool is a homemade device from a regular polyethylene package. To make it, you need to fill the packet with an extension solution, and then tie the neck and just cut one corner. Using such a device, you need to carefully fill the distances between the stone bar, trying not to fall onto their facial surface. After the solution hardens, it is necessary to smooth the seams with a plastic or metal blade.

- As a final stroke, after complete drying of the facade, it is desirable to be treated with a water-repellent solution. Such a facade will be additionally protected from weather conditions, and the stone will acquire an additional shine.

- In no case, do not start facing the facade in the frost. Such a temperature prevents the normal drying of the solution and glue. At the same time, too warm weather is also unfavorable for facing works. The hot surface of the wall does not provide the desired grip of the solution.

Facing: Design

- The process of facing the facade requires harsh compliance with technology. Alone to fulfill the entire complex even in accordance with the detailed instructions of specialists, the task is not the lungs. It is more expedient to such tasks using expensive materials, entrust specialized organizations. You need to start with the order of the project for facing work.

- Ideally, the facade cladding should be provided and calculated at the stage of designing the building. That is, the indicator of the strength of the walls should be known before the construction of their foundation.

- During the preparation of the project, experts take into account all parameters: the amount of finishing material, taking into account the likely amendments, perform volumetric modeling in order to exclude inconsistencies of parts during installation, and so on. To calculates, a series of modeled photos showing the facade lined with different angles so that the customer can Estimate the end result before approving the final project.

- This is especially important for large-storey houses that have such complex elements as columns, balusters, eaves and other architectural elements. It is not suiced, but do not hurry to refuse cladding, such a decoration of the building will serve for many years, the facade will look good and elegant.

Facing trim facing stone: Cost

- The averaged cost of finishing the facade of the house is 1,500 p. per m², the price of decorative stone is about 600 p. per m², and the cost of glue for outdoor use is over 500 p. for 25 liters.

- Preparatory work assesses approximately 700 p. per m².

- A total cost is added 30% for working with angular elements.

- Prices are presented for inexpensive materials with a standard set of works. More expensive consumables will naturally require much greater costs of acquiring and paying for installation.

Make the facing with your own hands will cost, of course, cheaper, but in the event of failure, losses will be essential. Discontinue the facade of your house with a facing stone, and it will transform, will acquire unique originality. Neighbors and passersby will pay attention, because it will be profitable to differ from neighboring buildings, and it will be comfortable and comfortable to live in it.

Start a discussion ...

Start a discussion ...