Terraced (deck) board is a modern building material that is made of wood-polymeric composite. It consists of crushed wood and purified polymer. Due to its composition, the terraced board combines all the advantages of wood and plastic. Externally, the material is similar to a solid whiteboard made of natural wood. In this case, it does not need to be painted, to cover with varnish or other compositions. How work is performed on laying a terrace board, let's tell further.

Instruments

Recently, a deign of wood-polymer composite (DPK) is gaining great popularity. A set of tools required to prepare a base for flooring from this material may be different. It depends on the following factors:

- Climatic conditions of terrain.

- The complexity of the work performed.

- The quality of the material with which to work.

Often, when installing this material, special skills or tools are not required, just those used when working with ordinary wood:

- So, for example, the decoping can be performed using the usual manual electron.

- In the board of DPK, you need to make holes for screwing screws. They are mounted on the size less than the diameter of the tapes. To do this, you can use a screwdriver or a drill.

- You may also need Bulgarian, roulette and construction level.

Preparatory work

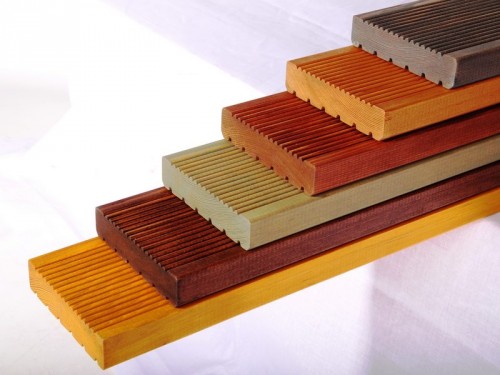

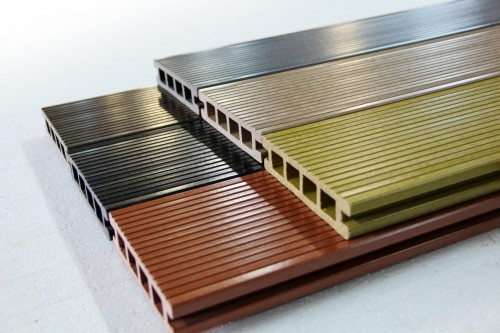

Terraced board: photo

First of all, you need to prepare the material used and the tool. Thus, a terrace board from larch should "get used to" to the local climate, so that it can successfully adapt to the operating conditions of the coating. For this purpose, after unpacking, it is left outdoors under a canopy for a couple of days. Before laying the board you need to decide which method for this is most suitable - open or closed.

When the mounting is separated, the fasteners will be noticeable. To do this, you will need self-tapping screws from a material with an anti-corrosion coating. Before starting work, you should make marking and drill holes. After that, with the help of screws, attach the boards to the base.

With the closed method of laying the material, the fasteners are hidden under the flooring. This will require special fasteners that are called clips. They look like metal plates with anti-corrosion coating. When they acquire them, it is usually calculated that on one square meter of the coating area will need 15-20 clips.

It is customary to distinguish between the styling of the terraced board "diagonally" and the "deck method". The first method involves parallel accommodation of terraced boards composite in relation to each other and to the walls. This method allows you to leave the minimum amount of material cropping.

The base for the terrace

The most important condition for installation is the construction of a solid foundation. As a basis can be used:

- Cement screed treated with a bituminous material with hydroizol.

- Wooden lags.

- Metal beams.

In any case, the base must be processed and cover with a special material that protects against the germination of weed herbs.

Before installing decoing from DPK, it is necessary to develop a water removal system that allows you to avoid the intake of the Earth after the cold. The basis is recommended to do with a slight bias towards the water removal. Tilt whose value is not more than one centimeter per meter, visually will be noticeable. Consider the accumulation of water can not be allowed on the surface of the floor nor under its flooring.

Laying carcass

- The basis (frame) when installing are lags from DPK. The boards need to be placed perpendicular to lagas, and it is recommended to do a maximum distance (300-400 millimeters) between the central axes of the adjacent frameworks. Exceptions are only places with an intense passage, where the gap is recommended to do no more than 250 millimeters.

- Do not forget that wood has the property to expand and shrink. Therefore, it is necessary to do for this stock in the form of a gap of at least 10 millimeters between the joints of the lag in length. From the DPK of Lag to the walls, borders, fences, carrying supports and drainage pipes should be the distance twice as much, i.e. Not less than 20 millimeters.

- Since a high probability of cluster on the surface of moisture flooring, you need to make the stock for water in advance. This should be completed while laying the frame. Water will flush if the lags lay parallel to the descent. If it is not possible to implement this, you should make a special water removal system. For this, lags should be slightly lifted and placed on special plastic supports.

- Placing supports can be done at any angle in relation to the terraced board. The price of work in any case will be low. In addition, perpendicular to the slope of the drain should be leaving the rupture of the lag.

- When laying the lag on the concrete basis, it is important to observe the distance between their supports - it should be no more than 400 millimeters. Exceptions are only cases of high load on the boards or using the Mounting method "diagonally". In the last two versions, the distance needs to be less than (340-380 millimeters).

- In order for the entire construction of the construction and, in particular, the flooring is well ventilated, the DPK lagows can be, for example, put on terraced plastic and metal supports. So that the ends of the boards of terrace polymer lay on the frame, it should be placed one supporting lag at each end of the design. It should be extremely neat. It is important that the framework turns out to be reliable and durable.

- You can also lay wider lags in places where the boards are connected. To the base, the material is attached to any way convenient for you.

Installation of a terrace board

- The laying of the material is recommended at an air temperature of at least 5 degrees Celsius. In addition, about one day before the start of the work, the material must be unpaved and give it to "ride".

- Laying the terraced board with their own hands begins from fixed structures. For example, from the walls. The very first chalkboard is fixed by self-drawing at an angle of 45 degrees to the support lag. The same applies to the last plank. And the holes for the self-tapping screw is recommended to be done in advance. At least two boards should be placed on one support lage. During the styling, you do not need to forget to leave between the wall and boards of the gaps.

- The next step will be the fastening of the terraced board to harvested lags with the help of special galvanized or plastic clips. Thanks to them, you can create a smooth gap along the entire length of the terraced board. Buy clips today is not a problem. In the lag, there is even a special deepening, where they are fixed with the help of self-tapping screws. Sequentially boards are attached to each point of support.

- The gaps between the ends of the placed boards should be at least 8 millimeters. To facilitate the work, you can use wedges of the appropriate width. The mount should be placed on each butt of the ends.

- Sometimes it is required to cover large areas with composite material. In this case, it is recommended to use the method of laying, which is called "in the dispersion". It lies in the fact that each subsequent row shifts half the length towards previous boards.

- After laying, first of all, you need to leave the ends of terraced boards, which come for the edges of the structure. After fixing all the boards, they should be aligned using a conventional disk saw.

Final finish

When conducting these works, it is necessary to close and process the open ends of the terraced boards. For this purpose, you can use special decorative strips of the same composite material. In lags, the holes under the screws are predetermined, after which the above planks are installed. Holes under the screws also need to be done in the end boards. The edges of the flooring is allowed to close the plinth. Sometimes for this purpose, aluminum or DPK are used. All decorative elements are better attached to their place with fixed limiters. It is important that there is still a stock moisture when installing. To do this, when installing decorative slats, it is necessary to make 15 millimeters in them. After successfully laying the flooring from its surface, accumulated dust should be washed.

Frequent Mounting Errors

Often, when performing work, the following errors allow:

- No ventilation gaps of the desired magnitude between lags are made.

- Screws (or other fastening elements) are too tightened.

- Water flows incorrectly.

- Composite boards are installed without compliance with the necessary gaps.

- Drainage holes are not made. Thanks to which water and other precipitations will be stamped on the surface of the structure.

Operating rules

- You should not allow the flooding of the design with water longer than 3-4 days.

- Do not use metal paper clips and blades to clean the surface. For this, brushes with a mild pile are suitable.

- Small defects on the surface (potholes, scratches) Gently remove sandpaper. Do it in a timely manner.

- Consider, the material after installation after 1-2 months may change a little shade.

Start a discussion ...

Start a discussion ...