The stool is an integral element, a mandatory device in any house. It is impossible to call it too expensive or a rare thing to be taken for his own manufacture, but the stool made by its own hands will certainly be more durable and elegant than the standard product from any store. We are talking about this today and talk.

Preparation for the procedure

As with any, more or less serious work, to the creation of a torere, you need to prepare well.

List of necessary tools

First of all, you need to prepare all the tools that you can come in handy. Prepare tools need different, as we look at various photos of stools, from which you can do work yourself.

The list looks like this:

- electrolovik;

- drill;

- screwdriver;

- screwdriver;

- drill;

- sandpaper, and ideally a grinding machine;

- small-gravel hacksaw;

- pencil;

- rule or corner.

Tuberet Materials

In addition to tools, it goes by itself, both the materials for the manufacture of torerer will be useful. Their list can be limited by such points:

- marker;

- roulette;

- varnish;

- bar;

- reiki;

- plywood

- foam

- the cloth;

- buttons, carnations, screws.

Possible options for stools

Since stools are considered a fairly common variant of seating tools, there are weights of their varieties. We believe that it is necessary to consider the most convenient and popular to know what you can make with your own hands.

The most popular options below:

- in the form of a conventional chair;

- a small stool suitable for balconies and for use as a stand. Often it has a height of no more than 25 centimeters;

- soft upholstery stool. Reminds the usual stool in the form of a chair, but due to the presence of a soft upholstery, it is often used in modern kitchens;

- folding option. All the famous folding stool on which grandmothers are sitting in the markets, fishing fishermen and dachas at the cottages.

To put all the points above "and", we suggest you view photos of stools that we led to classifications.

Drawing of herbal

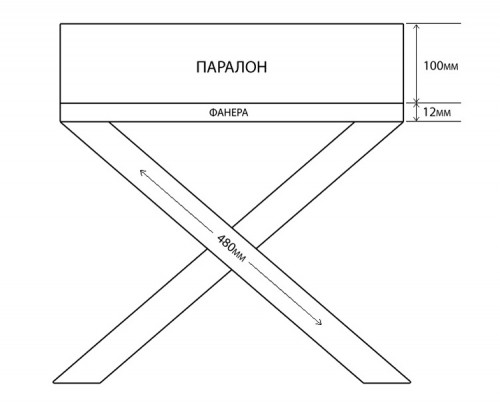

The stool that we want to consider the first is ideal for both the kitchen and a glazed loggia, where you can sit down and drink tea. It will have crossed legs, fastening for greater resistance to the construction of the timber. Taberet's seat will be covered with a cloth under which the foam rubber will be located. Such a soft stool will become the perfect seat in any kitchen.

Naturally, to do everything as it should, just follow the instructions, you need to carefully examine the drawing that we recommend you.

Characteristics of Bruckov

For the manufacture of a tool, we need to prepare bars. Their characteristics will be such:

- length of bars from which legs will be made - 48 centimeters;

- location of crossing legs - 24 centimeters from any of the sides.

Making a wooden stool

It is recommended that it is recommended to produce a strict instruction so that everything goes out exactly and without any inconsistencies.

We make legs and base

The first thing you want to take is the legs of your future stool. Go to the case:

- Take a pre-prepared bar and spill 4 special blanks from it, the length of which will be 60 centimeters.

- Make a speech that will be directed at the right angle of 45 degrees.

- Use a special stubble to dipping the legs, which can guarantee you absolutely exactly correct angle. So you will not spend valuable materials invested and redo the wrong work.

- After the manufacture of four legs, they must be copp on pairs.

- Make special grooves located on the place of crossing the legs. Observe the depth of the groove half the width of the legs.

- When the grooves are made, the legs must be extremely accurately installed in them without going beyond the boundaries. As a result, you will get a cruciform workpiece. Or rather - there will be two them.

- It's time to work on the stability and strength of the future stool. To do this, we need to make a special bar, fastening the crosses of the legs with each other. Brous's length will be the same as your future stool. And if you make a stool, the scheme of which was placed above, the size of the bar should be 60 centimeters.

- Prepare special grooves for screws of screws that will keep the fastening bar on both sides of the cross-crusades.

- Crerate crossmen with each other, screwing the groove to their centers of screws.

- Sell \u200b\u200bthe grooves for the screws of the screws with a wooden filler in order to make the stalls to be seen.

- But the hardening of the legs in the area of \u200b\u200btheir intersection is not enough. You also need to be copped with bars and at the top. Similarly, use screws (2 to each of the crossbars), which are attached to the bars of equal length to the cut at an angle of 45 degrees, part of the legs located on top.

- Get off the shutters of screws to make them invisible.

The legs are ready and you remained to paint their base in that color that you like most.

Perform sitting

Making a stool for the kitchen, a soft seat is something that must be present in its design. Fortunately, it's not so difficult to make it.

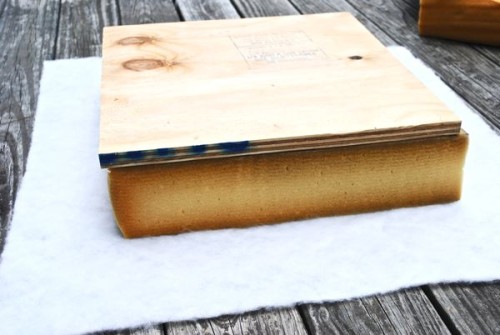

In order to make a durable seat, you need plywood. Its thickness is not too principled, but it is not recommended a thickness of less than 12 millimeters, as such a seat will be too harp.

We turn to the case:

- Take the circular saw, jigsaw or old, good saw, and drank with them a rectangular billet plywood, the dimensions of which correspond to the dimensions of the chair base. In our case - it is 60 to 40 centimeters.

- Take the scissors and cut a piece of foam rubber, the amount of which will be equal to the size of the seat.

- Next, cut gasket material. As for its size, it must exceed the dimensions of the seat by about 30 percent. This reserve is made for the purpose of possible future consolidation of matter under the seat.

- Lay the cooked materials in the following sequence: fabric, foam, plywood.

- Fold the corners of the matter under the cover of the future of the stool.

- Take the material that will serve as the upholstery for your chair. It needs to be put on the seat top and the underside of the stick by means of special buttons. Ideal keys with plastic caps. They look quite aesthetically pleasing, while holding the fabric in place very securely.

Congratulations, the part where you sit in the future also be considered finished.

Collect stool made of wood with their hands

Finally, a few details of the future stool, your autographic production harvested.

But the word "collected", we mean that they are made. And now they have to really gather to stool could start using.

Just say - the work is very simple. You just something to be ready to attach the base to the seat.

- Take the appropriate screws.

- With their help attach the seat to the base of the future of the stool.

- Use 2 screws on each side.

- If desired, you can mask the cap screwed screws wood filler.

Your kitchen stool made and ready for a long and reliable service.

Folding stool with his hands

What is a folding stool is known to all, and we know it, by the way, a very long time. It is an indispensable tool in the fishing, the outdoors, it is something without which one can not do at the cottage. And instead of having to go to the market and spend the money on a stool suspicious quality, it can also be made personally.

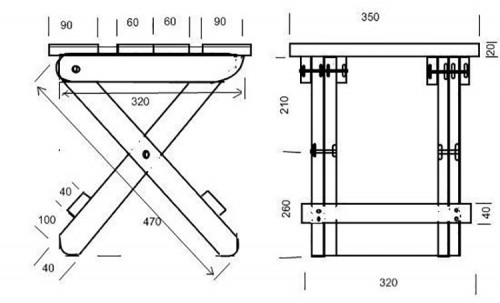

Stool: dimensions and drawing

The design of the folding chair is painfully simple, but still need to use the drawings that all went well and without much hiccups. Therefore, we suggest you to consider the perfect drawing.

Necessary materials

To create all the necessary items individually and assembling them in a single whole as a result, you will need the following devices:

- Fully identical bars in the amount of 4 pieces. Their parameters must be 47 per 4 and 2 centimeters in length, width, and thickness, respectively.

- Overhead pripers with length parameters, widths and thicknesses - 32, 4, 2 centimeters.

- Schedule under the seats in the number of four pieces. The overall parameters are the same as the prideracies.

- Bruks who will play the role of the seat. They also need four. Length is 35 centimeters, and the thickness is 2 centimeters. As for their width, 2 bars should be 6 centimeters, and another 2 - 9 centimeters.

- Bolts - 6 pcs. The length of the bolts should not exceed 4 centimeters with a hat. The diameter should be 6 mm.

- Self-tapping screws at 45-50 millimeters.

How to make a stool made of cooked materials

When all the materials and tools are assembled, you need to start making a chair.

- The very first thing that will be required of you is the placement of axial bolts. They are fixed on the legs of the chair, but by no means in the middle of each of them. This is an erroneous opinion, regarding the fastening of the bolts precisely in the center. In this case, the stool will turn out to be high, and will not be distinguished by the characteristics of stability. It is recommended to drill holes for the bolt closer to the top of the legs.

- Drilling a bolt hole, do not forget also about the fact that his hat must be drown in the hole. Provide this moment.

- Attach with the bolts of the crossbar under the seat to the top ends of the tabule legs. Pay attention to the fact that the crossbar four, and two of them need to be combined with internal legs, and two more - with external.

- In the case of correct assembly, you will have hinged parts in the number of two pieces.

- These details must be combined using wide seating bars. But do not forget to leave small skes from 1.5 to 2 centimeters.

- The attachment of bars occurs as follows: one of the bars is attached to the ends on the inner crossbars, and one more - to two external partitions.

- Now you need to install prices. They are installed on a 10 centimeter distance from the bottom of the legs. After proper marking and installation, they should be fixed using pre-prepared self-prepared screws.

- Turning to the next step, you will need to consolidate the middle bars. This operation must be performed slowly, thinking and calculating all moments. All because it is a very painstaking job. From the correct installation of bars will depend on the fact of how convenient and freely will be collected / disassemble your future stool. Medium bars are located similarly wide and external, one on the internal and external crossbar.

- The height of the future tokeret will be directly dependent on the place in which the internal bars will be connected. The ideal location of their attachment is 15-20 millimeters from a wide-type seating bar. If you adhere to this product manufacturing scheme, it will be the height of about 35-40 centimeters. Naturally, you can use other parameters, pushing out your own wishes.

Suitable materials and a small nuance

In the process of making a folding type, in general, you can use almost any tree species. But pine or birch are mostly recommended. By the way, the pine stool will have a very small weight, which is convenient for frequent carrying, for use on fishing trips and to the cottage. True, such a pine stool has a property to quickly break, and requires periodic tightening bolts that fasten the design.

There is another interesting design drawing, which will make it easily convenient to make even more convenient. You can attach a portable handle to the design of the folding toaster. Such a handle is fixed between the inner legs. If you initially take the bolts not 4 centimeters, but 6-7, there can be a very comfortable handle for carrying the product between the internal legs.

Making a stupid with their own hands. Video

At the end of our conversation, so to speak, to reinforce the work done, we offer you an entertaining video that tells how to make a stool with your own hands.

The video details all the nuances and the subtleties of the manufacture of high-quality, persistent and reliable chairs at home. After spending half an hour of his personal time, you will finally understand with all the necessary operations and you can safely begin work. After all, it is not for nothing that you can read 10 times, but seeing once - you will probably know how everything is done.

Start a discussion ...

Start a discussion ...