Did you decide to change the old wooden windows to new plastic? This is the right decision. Because plastic windows are durable, prevent the penetration of cold air.

Installing plastic windows with your own hands is a pretty simple job. Installation of metal-plastic windows can be made independently, regardless of whether you live in your home or in a high-rise building. The main condition is to clearly perform step-by-step recommendations.

Work plan:

- Do froze window opening.

- Dismantling the old window.

- Prepare window opening.

- Install a new window.

After measurements, you can choose a firm that quickly executes the order and makes the PVC windows.

There are no clear standards for the size of window blocks, therefore, almost every company can perform an individual order.

If you missed something in the process of measurements - there is a risk that the manufactured windows will not enter the window opening, or on the contrary, will be significantly less. So that this does not happen, it is necessary to be extremely attentive and clearly comply with all the recommendations. The same thing will be concerned and work on the installation of blocks. If you are mistaken, the advantages of plastic windows can be significantly reduced.

If you think large, the installation of plastic windows in the house will independently allow to take into account all the features and nuances of your room. Often, if the work is performed by the company, then there are cases where experts may not comply with the phased plan of the installation in order to save time. Then it turns out that the installation of plastic windows has a significant price, and the result will not meet the expectations.

We do measurements correct

Let's start with the most important thing - performing measurements of window openings.

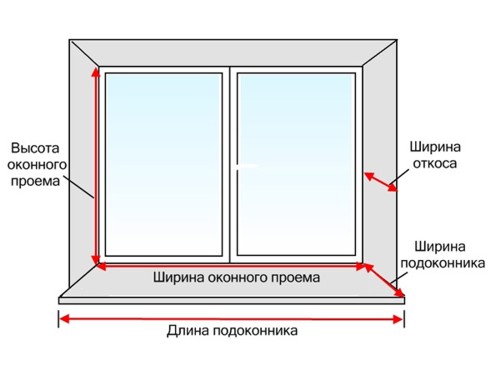

The picture shows the measurement of the opening without a "quarter."

To make measurements of the standard window, you need to measure the width of the opening.

The height of the opening is obtained like this: they measure the distance between the windowsill and the slope (top). In this figure (height) add the windowsill thickness.

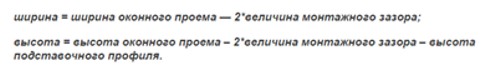

After that, you can calculate (pre-) the size of the future window:

Measurements need to be carried out three times each of the sizes: at the extreme point in the middle. It is necessary to eliminate errors in the calculations, because it is rare to meet perfectly smooth window opening. For the main indicator in the calculations, a smaller result is taken.

To check the curvature of the opening vertical, it is necessary to use a plumb, which is well pointed the tip. Water level check the circles along the horizontal plane. If deviations detected, then it is advisable to draw a drawing on paper, where the window frame is indicated as a rectangle with actual measurements. On the sketch, according to the level measurements, the necessary amendments are made.

Recommendations:

- perform measurements over all window openings indoors, because their width can be different. The height of all windows is usually the same, therefore, of all measurements, choose a smaller number;

- decide the window location. The plastic window is installed for two thirds of the width of the wall (the inner part). If you are then sowing the walls with heat insulating material, the window can be slightly advanced;

- measures of external sweeps. Measure the length of low waves or the width of the opening is added another half-meter to bend;

- measie connoisseurs. Consider it to overlap the battery by a third. If the battery is very recessed into the wall or in the opening, then it is desirable to additionally make small holes in the windowsill for ventilation (distance from the window - 5-10 centimeters);

- slopes are better to measure after the installation is made, as it is very difficult to get the width. The slope will be equal to the height of the opening plus a small margin on the "cutting".

If your window is located in an old brick building, then the window opening can have a "quarter". This moment can not be missed when measurements. To get an accurate digit, follow this formula:

Consider the cement screed under the windowsill and the tump. If it has a greater thickness, you can set a window with a large glass.

When measurements in private houses or in Khrushchev, it is desirable to bring down a nonsense from two sides in the locations of measurements in order to get an accurate size, because often instead of cement in the openings can be minvat or other insulation. If this is not taken into account, then when installing the window will not hold on long.

Methods of fastening

After the sizes are obtained, you can go to the company and order windows. Together with the consultants, the window configuration is selected: the presence of a sash, deaf part and accessories.

An important moment when installing the window - the fastening system. Systems are two types:

- When the window is attached through the frame.

- It is fixed with fasteners (shut-off armature), which is pre-mounted directly on the frame in the manufacture of windows.

The first option is most in demand, but during the mounting window you need to remove the sash to remain one frame.

The second option is more acceptable to install plastic windows with your own hands. With the second method, the risk of damage to the glass packs is minimized. But it should be borne in mind that when installing such a window block, it will be impossible to install the window itself, due to its decent weight.

Preparing for mounting

When you made an order and approximately know the delivery date of the windows, you can pre-prepare the room. The day before the alleged installation, remove furniture and carpets from the room. No opportunity to bring furniture? Build it with several layers of construction fither. The same needs to be done with the floor. This will protect the room from dust and construction trash.

When your order is delivered, you can proceed to the preparatory stage. First you need to clear the seat in front of the window. In addition, to cover the heating radiators.

Required tools:

- mounting gun for foam;

- electric drill;

- screwdriver or screwdriver;

- construction level or special plumb for mounting windows;

- hydroelectric system (at least seven meters) to align the horizon of the window line by the facade (wall);

- screwdriver;

- nail-holder;

- hammer (rubber);

- construction stapler;

- brush and tank for primer;

- sprayer.

In addition, it is necessary to purchase such materials:

- one or two cylinders of the mounting foam;

- hydraulic signable tape (for work in the room);

- hydropar permeable ribbon (for outdoor work);

- self-tapping screw (fix the frame to the block, a length of 120 millimeters, with a diameter of 6 millimeters with corrosion protection;

- heater for the windowsill;

- primer mixture;

- wedges assembly.

Dismantling of the old window

On that day, when you plan to install plastic windows, you can proceed to the dismantling of old windows. If you do not seek to keep the old frame, you can do not work especially above it. Fasteners are removed from canopies or burst along with screws.

Next, the window frame is written by a saw in two or three places and a nail-holder is approaching and getting every part. It is advisable to remove long nails in advance that hold the window block.

Directly under the window box itself are insulation and seal. They need to be removed.

Perfederate to remove partially or completely slopes. It will depend on what plans you have.

Then you can pose and remove the windowsill. It is also desirable to remove the "cement pillow" under the windowsill.

Building trash gather in bags and make out. In addition, you should remove the old window disassembled. Then the ends of the opening from dust and process to.

If you change the windows in the old room, then in order to avoid moisture around the perimeter, the opening should be layered by a layer of waterproofing material.

Installation and installation of plastic windows

Step-by-step instructions for installing plastic windows:

- Free the new double glazing from the sash. For this, swinging flaps are removed from canopies, remove the plugs and unscrew the bolts. As a result of these actions, you should remain only a frame with jumpers.

- Electrodel Make small holes for fastening anchors. You must have three mounts: on the side, on the bottom and top end. To make holes in the metal, use a special drill.

- Breeping window using anchors (diameter 8-10 millimeters).

If your window is equipped with a special fastener element (ears), then it is not disassembled, but only fix the mounts to the frame with screws. All necessary fasteners are supplied complete with a window.

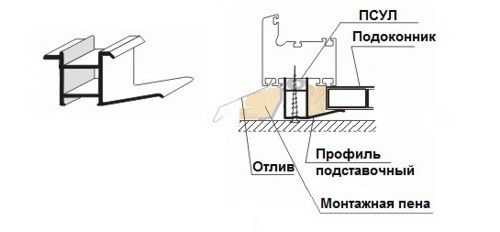

- It is further desirable to fill in a foam coaching profile. This nuance is not prescribed in Guest, and many installation specialists about him forget. Mounting foam need to fit space near the profile attachment to the frame.

Make it a day before the windows are mounted, so that the foam hardened and filled the space.

- In the lower part of the opening (in the end), wooden bars are laid under the edge of the frame.

- On the substrate bars (there may be plastic and enter the kit) install the frame or immediately all the window. The support is not removed, since the anchor is not able to withstand the weight of the window.

- Using mounting slats, the window is fixed on the sides. They are fixed between the window and the wall. With the help of a water level, the horizontal is checked. At the same time check the height of the installed window relative to other openings (if there are several windows in the room).

- Next, the window is aligned vertically with a construction plumb. If everything is in order - you can fix the anchors with the window.

- Waterproofs are inserted into a special hole along the edge of the window - the groove, and fill foam. Some windows of windows have fixing screws.

After the attachments are set, you can start an assembly of the window. Double-glazed windows are inserted into the frame and fasten the straps, first with the upper, and then the bottom and side. Latch with a rubber hammer.

After you have collected a window, you need to check the level. When the sash is open at 45 degrees and 90 degrees, it should not move, but open and close yourself. After checking the work of the flaps, they are tightly closed and sealing the gaps between the wall and the window.

Sealing gaps

According to the technology of installing plastic windows, to fill the gaps between the wall and the window, the mounting foam is used. In order for the foam over time, the seams are additionally sampled on both sides of the seams with special self-adhesive hydro and vapor barrier ribbons.

How to install the windowsill

The windowsill should be a little bit along the edges so that he goes into the opening and under the frame, and then rested into the profile.

On the edge of the opening, the windowsill should be 50-100 millimeters to "go" on the walls. Kolybami set the installation level and fill the installation foam. Instead of foam, cement mortar can be used. Then pinch the windowsill to the frame from the inside.

After the window is installed, it is necessary to leave it at rest for a day. After that, the sash is allowed to open to check how accessories works.

When checking the accessories, you need to pay attention to how tightly the sealant adjacent to the frame and how easily the entire system works.

Now you know how to install plastic windows yourself, and considering how much the installation of plastic windows from specialists is worthwhile, you will significantly save your family budget.

Plastic windows are installed on video:

Start a discussion ...

Start a discussion ...