The presence of a furnace foundation is a prerequisite for the functioning of this device, since it transmits all incoming load on the ground. When arranging this basis, it is necessary to know the fundamental features to build a functional and practical design.

Varieties of chick foundation

The foundation for the furnace in the house has a different location in relation to the soil level. In this criterion, it is divided into two types:

- ground;

- underground.

The base of the first type is used in the construction of furnaces on the second floors, and underground foundation structures are the basis for the construction of the furnaces of the first floors.

If the furnace structure is assumed in two tiers, a combined foundation is required for it. The load from the furnaces located at the first level is transmitted directly on the foundation design and further on the ground. The load from the furnaces erected on the second floors is initially on the supporting building structures, then on the base.

Recommendations for the construction of the foundation

- When erecting the foundation under the oven, it is important to take into account the weight of the structure. If its mass does not exceed 750 kg and its construction is supposed to be performed at the first level, then it is enough to be a reinforced concrete base. If the stove mass goes beyond the specified indicator, it is the basis for the construction of a separate base.

- For a furnace with a relatively small weight, it is recommended to choose the foundation of the column. In such a foundation, there are sufficiently swelled posts in the task of the piles, and the reinforced concrete plate placed on the ground performs as a support. This embodiment of the foundation structure received a reputation as the most reliable structure.

- Special attention requires the construction of the base for a brick furnace. In this case, it is important to prevent even minimal deformation changes in the foundation design. In the opposite case, there is a high probability of cracking in brickwork, which will continue to fragmentary or complete destruction of the furnace structure.

- The furnace foundation should take the load only from it. Do not connect the chimney foundation with the base of the house. There should be a gap of 5 cm between two grounds. This gap must be covered with sand in two layers. Or lay waterproofing material.

- In order to correctly determine the size of the future base for the furnace, it is necessary to proceed from the structure of the soil and mass of the furnace structure. Determining the depth of the foundation, it is necessary to take into account the level of soil waters, strength and bunchiness, the drainage depth and the level of the foundation of the house.

Before the start of construction, you need to take into account the density of the soil. This point is especially relevant in the construction of heavy furnace structures. The most appropriate are clay and sandy soils, as they differ in sufficient density and do not contain excessive moisture. If the soil has a loose inhomogeneous structure, before proceeding with it, it needs to be sealing.

Foundation under the oven photo:

Selection of material

For the construction of the foundation, you can choose the following raw materials:

- stone butt;

- concrete;

- brick Zheleznyak, etc.

The main thing in this choice take into account such an important circumstance as the strength of raw materials, because Material must have resistant to moisture. This condition is most relevant for wet soils, which are often equipped with a foundation for the furnace in the bath. The most suitable option for such soils will be a concrete foundation. But if another material is selected for construction, it is mandatory to use a cement solution when performing masonry. If the soil is dense and dry, in this case it is recommended to use lime or cement-lime compositions.

Foundation for a brick furnace

For brick furnaces, two types of foundation are the most suitable - it is pile and booton. Consider the construction of the foundation from the boot concrete material.

1. The initial stage of work involves the preparation of the pit, whose size is 15 cm should exceed the size of the foundation design.

2. After the recovery is ready, it is necessary to cover it with a rubble layer to 15 cm.

3. Next, we perform a thorough traam. Using the level you need to check the horizontal of the layer.

4. After that, the wooden formwork should be installed, the dimensions of which should be similar to the size of the foundation.

5. From the inside the formwork surface is treated with a rubberoid or high temperature bitumen. After that, the layer of stones with a diameter of about 12 cm is falling asleep into the formwork.

6. Space is formed between such large stones and to fill it in need to use fine crushed stone.

7. The layer formed in this way must be poured with a solution. It must be a mass made of 3-piece sand and 1st part of cement, the consistency of which should resemble a thick sour cream.

8. An important point in solving the problem, how to make a foundation for the oven is the performance of the fill of the furnace base. Depending on the size of the structure, this can be done in two ways. According to the first way, all construction is performed within one day. This option is suitable for small foundations. If the base has significant sizes to it, the second method is suitable, which provides for such a procedure:

- pour the first layer of stones and take a break for 24 hours;

- in the following, we form a second layer for this, after which a break again for a similar period of time;

- thus, we carry out the whole foundation.

9. The base under the oven made of bricks should be below the floor level by 7 cm.

10. At the final stage, the upper surface of the masonry needs to be well aligned. It should be done by level.

11. Then the surface is covered with polyethylene.

12. On this foundation for the furnace is ready, after 10 days you can begin the construction of the furnace.

Construction of pile foundation

This process begins with setting several piles by drilling. They will fulfill the support function for the entire design. The size of the foundation under the furnace is determined by the oven design dimensions. The construction process occurs in such a sequence:

- Using the boring, we make pits with a depth of 1 m and a diameter of 20 cm.

- On the bottom of the crushed stone and tamper.

- After that, by mounting the formwork from the frontieroid, pre-wrapped in the tube.

- Next, fill with the concrete composition to the lower level of the plate.

- After 10 days, plates from concrete material should be installed. It should have a thickness of 15 cm.

- At the final stage, we carry out the waterproofing of the base using a hot bitumen or runner.

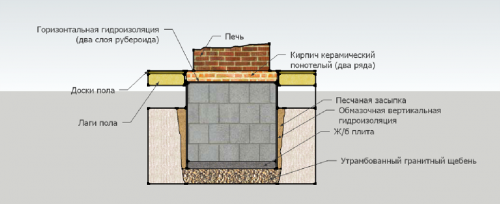

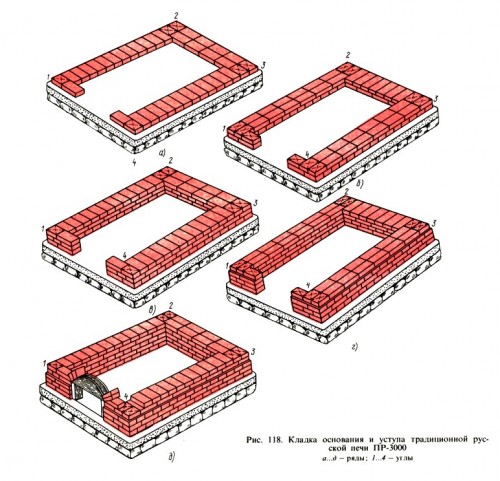

Foundation under the Russian oven

The Russian oven is a construction that has a lot of weight. Based on this circumstance, the foundation erected should be durable and have a direct docking with the Earth regardless of the base of the house. Before starting the building process, you need to remove the upper ground layer with a thickness of 10-50 cm. It contains many impurities of organic origin. This makes the structure of the soil porous, which is extremely not desirable for construction. Next steps are made in such a sequence:

- Work is starting with the preparation of the pit. The size of the pit must be approximately 15 cm more than the furnace parameters on each side. Thanks to this, setting the formwork will be much easier.

- For a uniform load distribution, the furnace base must exceed the size of the furnace by 5 cm.

- The bottom is covered with a filtering pillow from sand with a thickness of 20 centimeters. Perform a tamper.

- To ensure sufficient sand shrink, the layer should be poured several times with water. When performing this procedure, the layer will decrease. Therefore, you need to add sand to provide the necessary thickness.

- After completion of the shrinkage, sand should be aligned and properly tamped.

- Then we fall asleep the rubble layer, its thickness should be 20 cm. You can mix crushed stone with small stones or broken bricks. Such a layer should be covered with sand, which again it is necessary to pour water. Thus, the sand will fill the formed emptiness.

- Then you need to fall asleep another layer of rubble 10 cm in thickness.

- We make a tamper and labeled the runneroid two layers.

- To ensure fixation of the foundation you need to install a formwork. To do this, you can use boards or plywood sheets. From the outdoor sides of the formwork, the backups should be installed, which will perform the role of insurance.

- Between the edge of the trench and the formwork, the gap is 10 cm. The wall walls must be moistened.

- After filling the foundation under the furnace with a thickness of 5 cm.

- After the concrete mass is freezed, it is necessary to perform the installation of reinforcement.

- The reinforcement grid must be knitting with wires with wire.

- Then poured the second layer of concrete composition. It must be prepared from cement, sand and rubble in accordance with such proportions: 1: 3: 5. The process of filling the composition is performed in stages. Each layer must be tamped and water water.

- The final layer of concrete mass align and cover the tarpaulom to complete drying.

Foundation under the oven-fireplace

To perform such bases, a thick monolithic plate on two concrete styles is mounted. This foundation will be at its essence concrete stand under the furnace fireplace and at the same time fire apron. The design level should be equal to the floor. Then perform such actions:

- We form a concrete pillow, applying lighthouses.

- Then grow its surface through self-leveling composition.

- Next, set the formwork from the board.

- It is applied to the surface to the surface, after drying it with the help of glue on the foundation, we put the porcelain stonework plates. If the plates have a large size, the adhesive composition must be processed and the base and the surface of the plate. In case of non-compliance with this condition, there is a possibility of voids.

- To achieve the correct placement of the plates relative to the wall, make the markup on the basis using a pencil.

- The glue is applied using a special combblery with a teeth of 10 mm.

- Then, on the surface of the base one after another lay the plates.

- In conclusion, you should make sure that the horizontal plates of stoves should be ensured.

- On this base for the fire furnace is ready.

Conclusion

The pledge of a long service furnace is the foundation. It takes on the load and contributes to the safety of the furnace structure, regardless of the structure of the soil. The presence of a foundation avoids the appearance of cracks on it and any deformation changes during the operation of the furnace. Each type of furnace, depending on its dimensions, requires separate approach in the construction of the foundation.

How to make a foundation for the furnace on video shown below:

Start a discussion ...

Start a discussion ...