Many beekeepers face the problem of choosing high-quality and inexpensive hives for their farm. Each type has its advantages and disadvantages, but for many standard models there is always a topical question of the insulation of the object, since the bees should be wintering in a comfortable environment. Based on this, the beehive polystyrene is the best option for many farmers.

Features of the product

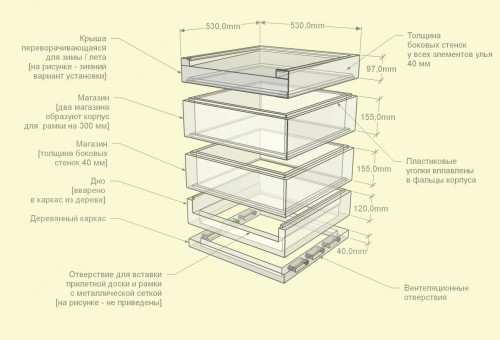

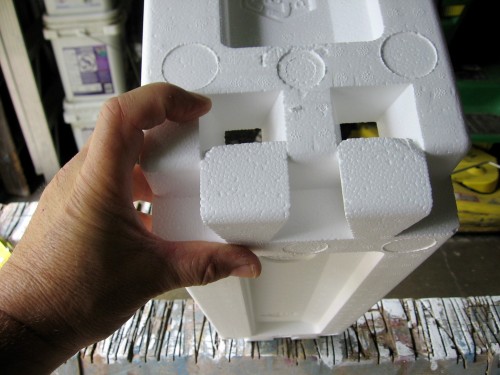

Make a hives out of polystyrene foams are quite simple, but before you begin work, it is necessary to determine the feasibility of their design. As a rule, a typical object is a case with dimensions in 440x250mm, having a lid, bottom and feeder. Wooden frames are mounted inside such a hive, the weight of which is about 10-12 kg.

Advantages The buildings of polystyrene foam beehive are as follows:

- small weight of the product;

- good indicator of maintainability;

- easy to manufacture and care;

- rodent security;

- low cost;

- high thermal insulation.

Among the main disadvantages This product can be allocated:

- low strength indicators;

- the ability to damage the housing by bees.

Preparation for the manufacture of hives

The initial stage in the design of structures is to prepare all the necessary materials and tools. Extruded polystyrene foam for hives can be purchased in a conventional construction store. Among the manufacturers are good reputation, such brands are distinguished as: "Penoplex", "Ursa", "Technonikol", etc.

To build a hive, you need to stock in the following instruments and materials:

- polystyrene foam sheet;

- self-tapping screw;

- small grain sandpaper;

- liquid Nails;

- a circular saw;

- poly-emulsion painting mixture;

- steel corner;

- stationery knife;

- screwdriver;

- metal ruler.

When choosing materials, some recommendations should be followed, which will reduce costs and ensure high-quality performance. Consider their more details:

- When choosing a mesh for ventilation, regardless of what your drawings do you have from polystyrene foam , it is worth reading such factors as the strength and size of the cell. The optimal variant will be the aluminum mesh with cell size up to 3.5 mm.

- Choose a stationery knife with a reliable rigid blade to ensure the evenness of the outstanding parts.

- The ruler must have a length of at least 100 cm.

- It is advisable to purchase a tree self-tapping screws, 5-7 cm long.

- In the case when the bee is inclined to excessively preplaught the socket, it is also necessary to acquire plastic corners with dimensions of 15x15 mm. Such fragments will be needed for inserts into the fold so that when removing the frames, the polystyrene foam does not crumble.

- Often to design bee hiles, a heater may be required in tiles, which is available for purchase in any construction store. Choose the thickness of the material depending on the size of your product, varying the indicators 20 mm, 30 mm or 50 mm.

Process manufacturing Ulya

After careful preparation of the necessary tools and the purchase of all materials, you can start making bee hiles. To do this, follow this procedure:

- The initial task is the markup of the sheet of polystyrene foam on preliminary calculations of the dimensional design of the future design.

- Then transfer the markup directly to the material field using the usual felt-tip and metal line.

- In the following by this, with the help of a circular saw or a stationery knife, it is necessary to cut down all fragments for the future design, moving along the assigned lines.

- In order for the edges to look smooth and neat, they must be pulled out by sandpaper.

- When all the elements are prepared, the manufacture of hives is coming to complete, and can be bred to a single case.

The assembly of all body fragments occurs in such alternateness:

- With the help of a stationery knife, it is necessary to do along the edges of each wall so called "quarters". This will allow combining fragments. Each such quarter is the value that is half the thickness of the polystyrene leaf thickness. It is also permissible to use a circular saw to cut each fragment.

- Attach both walls of the housing so that they come in protrusions into the right grooves and apply glue composition to the joints - liquid nails.

- After the glue dries and the joints are fixed, you can pull the design by self-draws. To do this, it is necessary to deepen each of them by 5 mm in the thickness of the sheet, placing in 10-12 cm increments. The screwing occurs from the outside.

- The finished housings of each segment must be collected into a single design, planting the upper part to the bottom.

- Carefully trace the smallest gaps or cracks during the assembly, because in polystyrene foaming products it is negatively reflected on the light and thermal insulation of the house, and also give the bee to fly away.

Recommendations for the process

In order to build a high-quality, warm and reliable foam foam hive, it is important to take into account a number of subtleties in the work:

- the most important rule in the manufacture of the product is the accuracy of calculation and size, since the appearance of inconsistencies in assembly leads to the formation of the cracks, and this entails undesirable consequences;

- after the construction of the hive, it is desirable to immediately make several plates for stock: the maintainability of such bee houses is good, but also the strength rate is low. Make additional fragments that can be easily changed in case of need.

Features of exploitation of polystyol beehive

When using this type of construction, as a rule, some features arise about which the beekeeper is worth knowing. Consider them in more detail:

- In the hive, made of expanded polystyrene, is used instead of the standard lap polyethylene film. Such body material absolutely does not absorb moisture, and in comparison with the wooden structure, the house has the best indicators of thermoregulation.

- The process of venting structures takes place through the hole in the bottom of the barred, the dimensions of which are typically 20-30 cm. It is also possible to ventilate the hive by opening the tap hole over the entire width of the housing.

- As is customary in a wooden house, the upper notches is not necessary, unless the beekeeper does not apply separation grating. However, it should be borne in mind that in the period of honey collection, insects will be very difficult to fly through the bars with a load of nectar. In this case, all the recommended year bonds do right on point with the help of a knife stationery. The dimensions of such openings are usually constitute 3x3 cm.

- In the spring, it is necessary to close the holes in the bottom to keep the heat in the hive.

- In winter, the entrance is reduced to 5 cm in size, with a hole in the bottom is fully opened. On the frame is desirable to put the film. Thus, the air circulation is provided through the notches and the lower opening. Remember that you need to completely eliminate the through passage of air through the club.

- Humidity control and its elimination takes place in the following way: when the bees breathe, moisture builds up in the form of condensation on the films and the walls of the hive, and then it just flows down into the hole. Weighty advantage foam polystyrene construction consists precisely in the fact that the house walls do not absorb moisture and owner of the apiary should not fear freezing, the formation of icicles and others.

- Beekeepers also need to insulate such a hive because the material body performs all functions of thermal insulation. In addition, installation of insulating cushion is no longer needed, and the socket can be limited only to a foam diaphragm.

Instructions for the production of polystyrene beehive on the video presented below:

Start a discussion ...

Start a discussion ...