Previously, the hive was built mainly from the tree, and today there are many new materials on the market, which are remarkably suitable for the arrangement of the housing of the bees. One of these materials is polyurethane, the hive is built on special technology.

Materials for ulives

If you proceed from the history of beekeeping, you can distinguish two types of hives according to what materials they were built.

- From natural materials - over the centuries, the ultrasound was made only from natural materials. At first they were built from burned clay, mainly in Greece and Rome, there were no minus temperature and the bees were wonderful felt in such a dwelling. Also, the beefell was made of straw, made from a cork tree and from stone. And in those countries where the harsh began to build the hives from the tree. And by the 19th century, when people learned how to build collapsible frameworks, housing for bees began to make only from this material. But not so long ago, science has made a breakthrough and created new synthetic materials that are much more suitable for the construction of hives than the tree.

- In the 70s of the last century, a polyurethane material was developed, which is considered harmless to bees and people. In developed countries, it began to be practically immediately used for the construction of the hives, and in Russia they became recently, but they quickly won popularity.

Advantages of polyurethane ulya

Recently appeared on the Russian market, polyurethane ultrasound quickly won the benefits of beekeepers due to a number of advantages:

- The bee does not feel in the polyurethane hives, the bee does not feel a sharp change of weather and temperatures, the material reliably protects insects from dampness and heat. Even if straight sun rays fall on the hive, the walls of the structure do not overheat, and the cold air does not penetrate them into the frost. All this increases the service of the bee house and retains life insect.

- Thanks to the spaciousness of polyurethane hive, you can place the breakdown of a good uterus in it and in it to accumulate honey reserve. The design of this evidence is that it allows you to change its volume, in the summer to make spacious, in winter less.

- It is very convenient for work, it is easy to disassemble the components, and it is possible to collect it again, while you can not be afraid to push the bees during the inspection.

- Such hiles are good to transport from place to place. If you know in advance that you will need to take out bees to the places where honeyst plants grow, then buy a hive that has special devices, which fasten its parts and in which there is ventilation.

- Due to the fact that all parts of the design have the same dimensions, then all work with them is simpler.

- Polyurethane hive is much easier than wooden.

- This material is considered environmentally friendly and certificates are attached to the hives.

- The material is resistant to environmental impact, it is not deformed and does not settle. Serves for many years.

- Thanks to the design of the sections, the hive is durable. And the material itself is dense, it is resistant to damage, the bees will not spawn it, like small predators.

Disadvantages of polyurethane ulya

The disadvantages of the hives of polyurethane are not much, but still they are:

- Specialists argue that this material needs to be shifted every five years or as needed.

- You can buy a poor-quality material that will have increased rigidity, a grayish color, it will skip dampness and expose of temperatures. Under the high temperatures of the wall walls will be heated, moisture will accumulate on them, as a result, this low-quality polyurethane is deformed. Such houses need to be additionally insulated so that the bees do not frozen in winter. In addition, poor-quality material is distinguished by harmful gases, which are etched by both animals and a person. Therefore, if you decide to buy bees for bees from this material, refer to the proven firms with positive feedback.

Features of construction

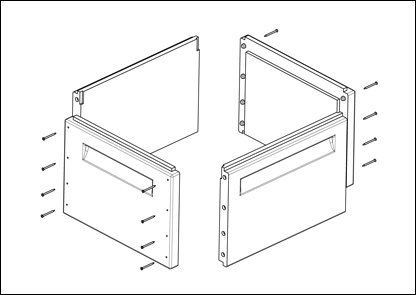

- Bottom. Its construction includes a mesh against ticks, pallet and the bottom itself. The mesh against ticks is usually made from a galvanized span, in which cells are about 0.2 cm.

- Pallet. It is made from different materials, for example, from plywood, galvanized tin, MDF. This item is needed to control the wintering bees, determine the degree of miscarriage of the bees, and in the case of insects by Askoperosis, can be able to control the appearance of mummy at the breakdown. If you are going to transfer hive to long distances, then the pallet from the bottom needs to be removed, so you will provide good ventilation and do not allow the families to be sealed.

- Lid. It has a combined shape with two working positions. It is usually the first position of the cover, and the second is necessary in order to move an apiary for long distances, in this case this position will provide good ventilation. When transporting bees, it is necessary to put a plastic grid under the top of the hive.

- Frame. All buildings are usually built with standard sizes. From all the sides, internal handles are mounted in it, so it is convenient to take it from any side. In the case there are 10 frames with a gap towards not more than one millimeter.

- Frame or transitional bottom. It was developed for an intense form of beekeeping, with its help can be implemented in reality a comfortable technique of two-way beekeeping. Families in this case are divided into such a way: on the housing of the hive it is necessary to put a plastic mesh, and to put the frame on it, the same frame is used as another pilot.

Collect the housing of the dwelling for bees can be screwed up to 1 cm in size. The glue is applied to the place of docking. To make it easier and rather, the assembly passed, you can make a template from boards and plywood. The finished polyurethane design must be painted, otherwise the material may be damaged by the impact of ultraviolet rays.

Nothing is difficult to care for beeshole. Its cleansing should be carried out very neatly and the chisel, then the parts are washed with a warm one with the addition of soda. Sometimes parts are hampered by steam, after that the entire design is well dried in the sun. Please note that at the corners of the hiles, propolis is not necessary to collect, this component is a kind of immunity bee in the fight against diseases. It is necessary to paint the hive as needed, when the protective paint is fading. The hive is easily disinfected by drugs, it also outweighs the choice of material in favor of polyurethane

Production technology

The technology of production of polyurethane hives is characterized by simplicity. They can be both cast and assembled their individual details, which are interconnected by polymer glue or self-drawing. The type of construction depends on what a special metal press form is used to fill the material, it can withstand the pressure from the expansion of polyurethane. The design is created in this way:

- The walls of the mold are lubricated with anti-adhesive lubrication.

- The form is poured polyurethane in liquid form. The number of components depends on the thickness and dimensions of future houses for bees.

- Polyurethane foams, becomes more and pouring, becoming solid.

- Ready Beehive paint outside.

Equipment for filling material depends on the shape: the volume of the product is greater, the power is the fill machine.

Due to the fact that all parts are poured in the molds, they are all interchangeable, this is another advantage of polyurethane hives before wooden. It matters not only in large apieges, but also on small.

It is no secret that in order to make a good wooden hive for bees you need the skill of the joiner and the presence of high-quality material, besides during the assembly, the details may not fit and have to customize them to each other. What you can not say about the evils from Polyurethane.

If you have a big apiary or a whole beekeeping economy, then you will be more profitable to buy polyurethane evidence, but to make it yourself. But for this you will need to purchase equipment and material. But you can always be sure of the quality of the designs, they will always be available as soon as you need.

Profit from the hives can be obtained not only by doing beekeeping. You can make houses for bees for sale. You will have a stable income, because the demand for this product is permanent.

Start a discussion ...

Start a discussion ...