The shovel is one of the most essential labor instruments, both in the life of the gardener and in many working professions. During operation, first of all, attention is paid to the basis of the shovel, if it is quite sharp and durable, then it is much easier to work with it, but the cuttings defects remain aside. However, if suddenly the cutlets are very long or opposite - too short, shaky, wood threatens to disappear, then it is absolutely impossible to work, and labor efficiency is reduced to zero. In addition to the usual wooden, there are also aluminum cuttings for shovel. They are famous for greater durability and resistance to erosion. In this article we will tell about how to make a stalk for shovels.

How to choose a cutlets for shovel

The main problem of masters when choosing a cutlery is a rush, as well as often ignorance, because the first thing that came across and already at home there are quite large difficulties with the joining of the cutlets to the bayonet. In order not to make such mistakes, you should at least familiarize yourself with the varieties of shovel.

There are 3 types of garden shovels:

- popping;

- digging;

- universal.

In each of these types, there are significant differences in the thickness, sizes of metal web and lining, and therefore the cuttings must be selected based on these parameters.

First of all, when choosing a factory cuttle, it is worth paying attention to defects, which will continue to largely affect productivity and durability of the product:

- rotten places;

- swirls;

- depreged;

- cracks;

- jar;

- worms;

- skoli.

The surface of the cutting should be smooth, smooth, with uniform color. Particular attention is recommended to pay the coatings - it must be lacquered or paint that prevent accidental offering under the skin, and also remove from premature damage to the material and exposure to the external environment.

Choosing wood

Despite the widest range offered by the construction and horticultural market, there are several reasons why it is worth making a cutlery for shovel with your own hands. First, for the manufacture of cuttings for shovel in industry, poor-quality materials are often used, namely wood waste. You can control the process at each stage of production and make a cutlery from the highest quality and durable wood.

Secondly, often manufacturers do not pay due attention to the drying of the product, as a result of which the deformation and the occurrence of cracks occurs. The optimal percentage of moisture of the purchase of wood should not exceed 15%. If the excessive moisture content of the purchase product can be independently drying it, however, in this case, defects are not excluded due to the poor quality of raw materials.

Thirdly, the cutlets are calculated as universally universally using the machine for use for any tool. As a result, it is not deep enough to sits in a shovel and needs a manual fit.

Often sellers carefully mask all sorts of defects to increase the price of the product. At the site, it is not so simple to reveal it, however, during operation, over time, they begin to manifest themselves and bring great inconvenience.

In addition, there are difficulties with the definition of the material from which the finished product is made. After all, not everyone is capable of a professional level to distinguish one variety of wood from another, however, the cost of the product depends largely on this factor.

Undoubtedly, most often the products made by their own hands are inferior by an industrial aesthetics, but with a competent approach, one hundred steps will cost them in their functionality, convenience and quality. To obtain a strong and comfortable cutter for the shovel, it is better to start with the selection of the material. It is from him that the strength and appearance of the finished product depends.

The main varieties of wood, which can be used for the manufacture of cuttings shovel:

- pine - Despite the fact that the material is quite easy to process and due to the impregnation with resins is not afraid of moisture, it has a very small shelf life, because it is very fragile, low density. At the same time, the large percentage of products presented in the market is made precisely from pine, since it is a cheap and easy-to-process wood grade;

- birch is a strong enough, inexpensive price and easy to process. The main advantage of its advantage is the ability to withstand serious loads. The optimal version for the manufacture of a cutting;

- beech - in quality is very similar to the birch, however requires longer processing, since the resin content is minimal, and additional protection against humidity is required;

- poplar - lightweight wood, behaves well when processing, is characterized by sufficient strength and durability;

- oak - compared to all materials the strongest, but very heavy by weight, and therefore the cuttings for the shovel of it are rarely made - the tool should be quite easy to work comfortably to work. In addition, the oak is quite difficult to hand-made handling, and the cost of such a cutting will be unreasonably high.

Thus, for the manufacture of cuttings for a shovel is best of all birch breeds. This material can be found without much difficulty on the sawmill or on the market. It should be checked for cracks, peeling or other defects. It is advisable to choose raw materials with a minimum number of bitch or without without them.

The length of the shovel cutter is worth paying special attention. Optimally, when the length of the product comes to the shoulder of the employee, which is approximately calculations of 140-180 cm. However, this value may vary depending on the individual preferences, the growth of the person and the use of the shovel in the future, because too long a stalk can deliver some inconvenience in operation .

How to make a stalk for shovel

The classic shape of the cutting for shovel is round. It is ideal if the work is assumed in the process of work. Most of the products presented in the market have a round shape, but there are also square cuttings. They are less popular and used exclusively at will. In the instructions described below, we will tell about the manufacture of a circular cutter. With elementary carpentry skills with work, any patient and hardworking owner will cope.

Required tools:

- plane;

- knife;

- saw on a tree;

- hammer;

- sandpaper;

- impregnation antiseptic;

- glue;

- varnish transparent wood or paint.

The manufacture of a stalk for shovel occurs in several stages:

- First you need to choose the material from which the cuttings will be made. In order for the finished product to be perfectly smooth, you should choose a board or a branch twice the strength of the supposed diameter of the shovel. Carefully inspect it for the absence of bends, branches, bitch and other defects.

- Next, it is necessary to dry well for the wood for 15-20 days in the sun. If you use a special workpiece, then this step can be skipped.

- With the help of the plane, it should be removed everything too much and bring the blank to the desired volume of wood, align the level and scrolling movements to align on the axis.

- Thus, you will get a rough workpiece, which is further selected. If there is a special grinder in the undergraduate tools, it greatly simplifies work. If there is no grinding machine, it follows to start walking on a blank with a large sandpaper, and then treat it with small grain paper.

- At this stage, it is necessary to re-examine the workpiece, because the grinding removes a significant layer of wood, and you can reveal and remove hidden defects.

- In the event that not a special purchased billet is used, then the cuttings of the anti-corrosion suspension should be impregnated and give drying within 24 hours.

- The final stage is the coating of a stalk varnish or paint. To do this, you need to walk all over the area in 2 layers. The second layer is applied after complete drying of the previous one. This process is optional, but it allows you to increase the time of use several times. In addition, the lacquer coating reduces the risk of making hands during operation.

How to put a shovel on a stalk

From how well the shovel is attached to a stalk, a lot depends. First of all, the convenience of work and productivity.

This process can be divided into several stages:

- Sharpening - the end of the cutter must be sharpened so that it fit to the bayonet inlet.

- When the cutlets arrive until the middle of the groove, you need to adjust the shape of the cutting in accordance with the irregularities of the groove.

- To stop the cuttings did not rest in the ground, its end should be slightly crowded at an angle to the blade of the shovel, so that it does not go beyond the groove. This can be made ordinary knife.

- Then you need to polish the pointed end and pour with antiseptic impregnation, so that the cuttings do not rot on the cutting or insecting insects insects. Leave the workpiece until the impregnation is completely drying.

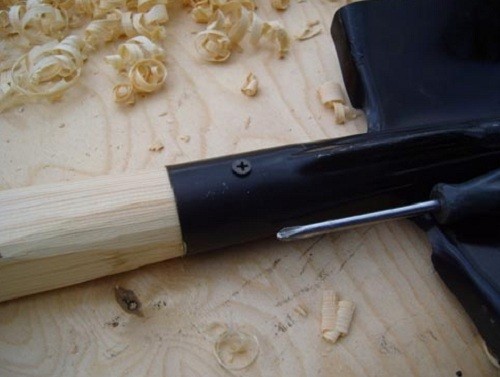

- When the impregnation dry, it is necessary to wear a shovel on a stalk and a few strong harsh blows about a solid surface to drive it up to the very end of the groove, and then secure self-reliability for reliability.

Finally, we offer to look for a useful video, in which the process of manufacturing a wooden cutter for shovel is shown in detail:

Start a discussion ...

Start a discussion ...