Progress does not stand still. This postulate can be perfectly demonstrated on the example of beekeeping. If earlier hives were made predominantly from wood, today various materials for independent creation of bee houses are available. But we are interested in the technology of production of the so-called Finnish hives.

Polystyrene foam is a universal material with high thermal insulation qualities. Among its merits is the availability of repair and low cost. If we talk about minuses, you should highlight low strength and vulnerability to bees. Insects are often not averse to try tooth of hive. You can buy finished polystyrene foam hives in specialized stores, but devices are quite able to assemble yourself. To do this, you will need some tools, skills and healthy trolics of enthusiasm. So how to make the famous Finnish Bee Box hive?

Tools

The main building material can be found in abundance in any buildingman. You will also need:

- stationery knife;

- glue;

- self-tapping screw;

- metal line;

- Screwdriver.

Do not forget also about the grid for ventilation mounted in the bottom area. The best choice will be metal or aluminum mesh. According to experts, with polystyrene foam is managed many easier, especially beginners. For this, all major parts are prepared on the markup of drawing schemes. You can cut the material by a simple stationery knife, and to connect - with the help of glue and screws.

A little about the nuances

Uli Finnish should not have cracks or gaps. Otherwise, unwanted light, the wind falls there, the microclimate is disturbed. Correcting correctly, it is recommended to flexibly glue all the details by scrapering with self-drawing at a distance of 10 cm from each other. Do not throw out the extra material that can be useful for repair.

The case in appearance resembles a box, the standard size of which is: length 450 mm, width 375 mm, height 240 mm. The design includes 10 frames 435x230 mm. A fairly small size of the box leads to an increase in the volume of the bee nest, and not separate frames, but to all the case. The width of the frames can reach 20-35 mm. There are no certain restrictions in this regard, but it is easier to maintain thin-walled parts.

Regardless of what sizes you select, cut the blanks with a 5 mm reserve. For processing edges of the material, sandpaper is used, with which you can not only align the edge, but also reduce the extra volume. When choosing glue, remember that polystyrene foam is unstable to organic compounds. Drying the body is about a day.

After drying on the front and rear wall, folders are installed to subsequently embed the frame. Dimensions are: width 11 mm, depth 20 mm. Then in the recesses are placed slices of fiberboard, which will become a reliable support for the frames of the frames.

With all the built-in elements, the total weight of the hives reaches 800 g. Based on complex climatic conditions, in which the Finnish hives are operated, manufacturers install weightlifiers. Take care and you about it. It is also recommended to paint the external surfaces to protect the material from the destruction of the sun's rays. As a processing agent, paint is suitable without solvents and acetone in the composition. So let's summarize:

- Prepare material and tools, cut the sheets in size with a 5 mm reserve. You can use standard sizes or own.

- Treat the edges of the expanded polystyrene with sandpaper and align all parts strictly in size.

- Spread all parts and let it seek the case.

- Put the folds on the front and rear walls of the width of 11 m wide, a depth of 20 mm. They will accumulate pieces of fiberboard to reliably fix the framework.

- Color the outer parts of the paint without the content of solvents and acetone.

- Install the metal grid on the bottom.

Advantages of polystyrene foam

Newbies, wondering on an independent manufacture of hives, often asked what Finnish hive reviews. Modern bees "collective farms" from expanded polystyrene have many advantages.

- First, ease of maintenance, durability.

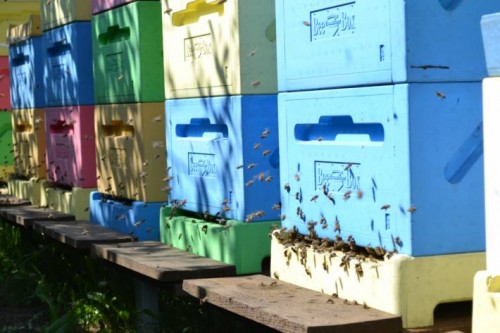

- Second, the possibility of transportation. Good stability is achieved by means of a multicompute setting of hives.

The bee houses from polystyrene are not subject to destruction and dampness, odor appearance - frequent satellites of wood hives. The cost of the material-raw material is democratic, which you can not say about the analogues. In the hives of this material, the pathogenic microflora is not developed. Polystyrene foam prevents the reproduction of frequently occurring bee diseases like swarratosis. Regardless of the street temperature, inside the case, subject to high-quality assembly, optimal conditions are stored for bees. In winter, such hiles do not require insulation. They have even critical temperatures -50 ° C. Mol also does not attempt to artificial material.

For bees, hives are comfortable for living due to the flyer, which serves as the "front entrance" for the workers' collectors of honey. Insects, immersed by pollen, without preventing the relatives, penetrate the hive. Other representatives of the fauna will not be able to access a narrow pilot.

The case is even taking into account the honey is quite lightweight, which facilitates the service of the uly one butter. Without assistance, an adult man can move a mobile bees house, transport. Sides in the form of snow, hail or rain with wind also do not threaten designs. All this once again proves that Finnish polystyrene is the most optimal option for the butter.

Disadvantages of polystyrene

- combustion;

- lack of natural ventilation;

- vulnerability when cleaning propolis;

- the appearance of mold and dampness on the bottom.

The main minus is high flammability. Also, be sure to consider the ventilation system, since artificial material is inclined to accumulate steam and do not pass air flow. During transportation, breakdowns of structures are possible. The structure of "foam" is also vulnerable when cleaning the walls of the hive from the propolis layer. As a result, the healing propolis is mixed with the intolerable grazing of polystyrene foam.

With prolonged use of part of the body, it becomes difficult to separate from the propolis, which scores all the slots. In addition, the material becomes a victim of bees that are noisily gnawing - make trays. If you do not take care of the installation of the mesh bottom, such structures will fill the smells of mold and dampness. It is not necessary to talk about the quality of honey in this regard.

In general, Finnish ulves of polystyrene foam is the best option for beginner butubs. The material is unpretentious, easy to use, is available. You can make it possible to make it possible for several hours to make the beehive size, prepare enough material and tools.

Start a discussion ...

Start a discussion ...