Hydraulic is called machines that report the mechanical energy of the working fluid or, on the contrary, produce energy from it necessary for further transmission to the worker. They have long been used in various spheres of human life. If the fluid transmits the energy to the mechanical parts, then such devices are called hydraulic motors. If the reverse process is carried out, then the speech is already on hydraulic pumps. We will tell about their device and nuances of work further.

Characteristics of an axial piston pump

To date, hydraulic machines (hydraulic machines and hydraulic pumps) have been widely used. They are used in various fields of industry, as well as in large households. Since such installations are able to withstand heavy loads, they effectively apply on technical enterprises, in water supply plots, apartments and houses. They also found their use also in the power plants of spacecraft.

The most common volumetric and blade units today. The worker in the latter is a special wheel with blades. Their interaction with the working fluid activates the energy transfer process. In this case, in the blade hydraulic pump, the energy is transmitted from the wheel to the working fluid, and in the blade engine, on the contrary.

The operation of volumetric hydraulic units is carried out by changing the dimensions of the working chambers. They, in turn, are connected to the input and exit nozzles. The compound process occurs in stages, after certain intervals. Such devices include piston, axial-piston pumps, gears, screws.

Advantages and disadvantages of an axial piston pump

The advantages of an axial piston unit:

- If you compare the characteristics and operation of an axially piston pump with other similar aggregates, then they are quite compact (the weight of the installation is relatively small), and at the same time they have quite high power.

- The working bodies have small size and cause a small moment of inertia.

- In such machines, it is possible to quickly adjust the frequency of rotation.

- In addition, from the advantages of such aggregates it is worth noting that they are capable of working at high pressure. At the same time, they function with a relatively high rotation frequency and have the ability to change the working volume.

- The range of rotation in such aggregates is from 500 to 4 thousand revolutions per minute. This is an undoubted advantage compared to hydrometers and radial-piston-type devices.

- Such machines without any problems can perform their functions at a pressure of up to 35-40 megapascals. For comparison, radial-plunger devices have a maximum working pressure of 30-35 megapascals.

Of the disadvantages, the following should be selected:

- High price.

- Pretty complex design.

- Low reliability. Possible frequent breakdowns with improper operation.

- Substantial pulsation of feed and consumption.

- Large pressure ripple throughout the system.

- Due to the high difficulty, troubleshooting axially piston pumps may take a long time.

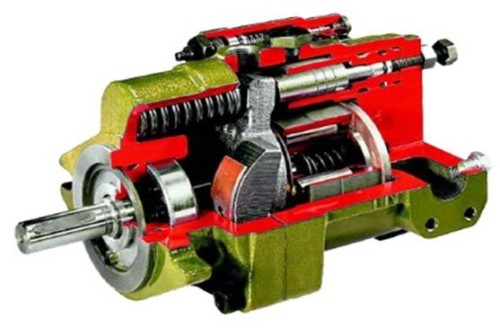

The device of an axial piston pump

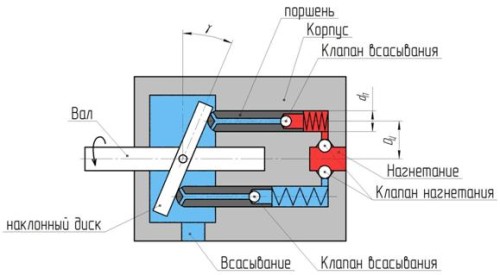

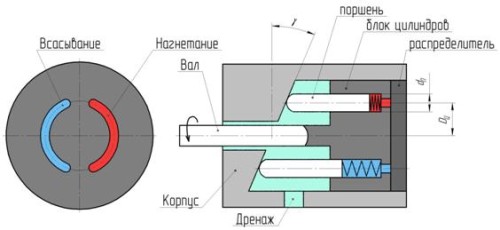

This unit consists of the following important elements:

- Pistons or plungers. Are in the composition of the cylinder block.

- Rods.

- Presenter (main) shaft.

- Thrust disc.

- Distribution mechanism.

Principle of action of an axial piston pump

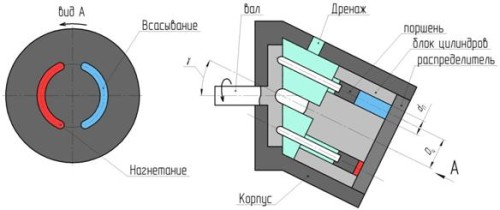

The unit is based on the effects of a rotating shaft on a special cylinder block. In this case, there is a translational movement of the pistons along the axis of this block. Thus, reciprocating axial movements are performed, thanks to which the unit received its name. It is also relevant for an axially piston pump unregulated.

Studying the principle of operation of an axially piston pump, it can be seen that when the pistons moves in the cylinders, suction and discharge occurs. A compound with pressure and suction lines is carried out sequentially through special windows in the distribution device. To avoid faults, the cylinder block is performed so that it is tightly pressed to the distribution device. To ensure reliability, the window of this block is divided using special sealing jumpers. In order to reduce the hydrowards during the operation of the unit in these jumpers, throttle grooves are made specifically. Due to this, it is possible to evenly increase the pressure of the working fluid in the cylinders of the axial piston pump. The price of the aggregate is respectively high.

Cylinders placed along the rotor axis are used as operating chambers in the units of this type, i.e. axially. Promescribers in this case are pistons.

The scheme of an axial piston pump

According to the design features, all aggregates can be divided into two large groups:

- Devices equipped with an inclined disk.

- The aggregates equipped with an inclined cylinder block.

The first group of devices found its use in the actuators of units operating, as a rule, in medium and heavy modes.

Today, axial-piston pumps are collected in several schemes.

- First of all, it is worth considering the option with a double non-melted cardan. According to this scheme, the equality of the angles between the axis of the intermediate shaft and the axes of the slave and the drive shaft are achieved. Therefore, during the operation of such an aggregate, all of its parts (slave and leading shaft) function synchronously. As a result, the work of the cardan shaft is greatly facilitated. After all, it interacts directly with the disk by means of which the transmission of torque is carried out.

- In the design of the hydraulic pumps with a point touch of the pistons of the inclined disk there is no cardanov and rods, which greatly simplifies their device. But to start the unit, its pistons are required to preliminarily push out the cylinders and press the inclined disk. According to the specified scheme, hydromachines are made of low power. For example, G15-2. To date, it is the installation of this type that are considered the most popular.

Housions axial-piston adjustable (Products of the H and S)

The aggregates from this series, equipped with an inclined disk, are often installed on bulk waterways, where in the system except the nanos there is a hydraulic engine. Both are working according to the closed scheme. In addition, such a nanos is installed in road seals, combines and automatic concrete mixers. They are easy to manage, and they have small dimensions. The flow of the working fluid when the inclined disk rotates rotates in the opposite sides, which causes the device operation.

Due to the presence of a hydraulic distributor in the form of a module, it is possible to attach the control systems (SU) of the following types:

- Electric three-position Su (ER). This system is used to drive through the three-position system (this is the position: on - off - incl).

- Hydraulic Su (HD). It is a kind of control lever. It gives hydraulic signals to all the mechanisms of the unit, thanks to which the inclined disk is kept in the desired position. This SU is used in complex layout units.

- Hydromechanical Su (MN). Provides maintaining an inclined disk in the required position, thereby working the pump in the specified mode.

- Electric Su (EP). This system, changing current strength on several proportional magnets, allows for a smooth change in the working volume of the unit.

Start a discussion ...

Start a discussion ...