The key to successful construction is competent planning. And the construction of the house of the brick is no exception. From the right calculations, it depends not only if you have enough material for building a building, but also how much you can save on the purchase of everything you need, how much will transportation cost, how long will it go for construction as a whole. In this article we will touch everything you need to know to calculate the brick on the house.

Factors affecting brick consumption

Each second city resident dreams of a private house with a small garden, a garden or, maybe a pond. This dream is quite feasible, and to build a house can anyone, but the prevailing majority are scared not so much the most important ideas, how many complexity of preliminary calculations. In fact, everything is much easier than it may seem at first glance.

But before you begin to operate with dry numbers, you need to learn the maximum of the material with which you have to spend alone long hours. Brick consumption depends on several factors: the method of masonry, the size of the product itself, the thickness of the seams, the thickness of the walls. Consider each of them in order.

There are several types of masonry, each of which is designed to build walls of different thickness. A single brick is used for the ordinary wall, for a thickened - one-time, for a powerful carrier structure - double. To determine which method of laying you will be applied, follows at the design stage of the house. Only when all the walls and partitions are displayed in the drawing, you can start calculations.

Walls depending on the type of masonry can be thick from 12 cm to 64 cm. To ensure the heat resistant rates, the thickness of the walls of full-scale clay brick can be at least 1.9 cm. However, the thick walls are extremely difficult and expensive, so to reduce the load on the foundation And cost reductions External walls are mainly made from the hollow material. You can also use a full-length, in which then make emptiness and fill them with thermal insulation.

Brick masonry methods:

- In the clamp - bricks are put on a hard solution, which completely fill the seams. Each subsequent element is tightly pressed against the masonry (hence the name) with the help of the Celma - the edge is selected part of the solution to the already laid, and the next brick move towards its edge. When the brick is almost pressed, the culma is pulled out, and the solution that she kept remains inside, hooking the face. Surplus removed and used to lay the next item.

- This method is relevant to masonry on a larger cement mixture with pioneered seams. The solution is prevented by non-cell, but the edge of the stacked brick, starting from the distance of 8-10 cm from the laid. So brick collects a solution on a vertical edge, which is pressed against the adjacent element. Surplus are collected and filled with vertical seams.

- With trimming - this method combines receptions of the two options described above. They spread the cement mixture on the same principle as for masonry in clamp, but put bricks.

The next important point is the thickness of the seams between bricks. On average, it should be 10-12 mm, but not more than 15 mm. The joints of the seams must be carried out every 4-5 rows until the solution hardened.

There are two methods of the seams:

- In the void - with the outer part of the wall between the elements, unfilled gaps remain. This method is mainly used for walls that are planned to be placed.

- In the sublica, the gaps from the outside of the wall are filled with a solution with a brick face with a face. As a result, smooth smooth walls are obtained. This method is also used to masonry fireplace pipes.

An important role is played by high-quality stacking of seams. So that the load is uniformly distributed, and the wall has not cracked, it is necessary to prevent the coincidence of the seams in the neighboring rows, but to make them with a little displacement. If you make a dressing in one row, bricks, laid across (tilenk), should be alternate with those that lie along (spoonful). If the bandage is multi-row, the spoon should be alternating with the thage-in 5-6 rows. The reinforcement of the design of the grid is also carried out through 5-6 rows of masonry.

Choice of bricks

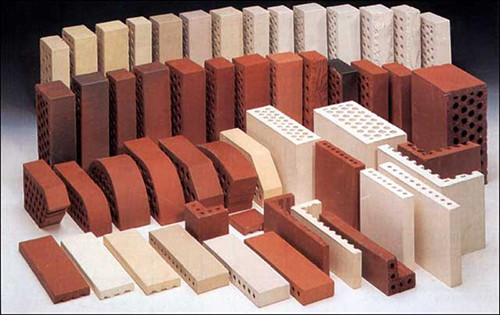

In the construction of people in construction distinguish only two varieties of bricks - white and red. In fact, everything is much more interesting, and the correctly selected brick will help not only make the house stronger and warmer, but also save on transportation, purchase and time that will go to the installation.

The separation of bricks on red and white, in principle, right. These materials are distinguished by the composition - red are made of clay, and white - from the sandy-limestone mixture. Accordingly, the performance characteristics and the cost of these products will be different. So, red bricks from burned clay are suitable for the construction of almost any structures, ranging from multi-storey houses and foundations, ending with mangals, garden tracks, etc. It can also be used for facing facades.

I wonder: clay bricks can be not only red, but also brown, orange and even pale yellow. It all depends on the quality and properties of clay used for production. This allows you to embody interesting designer ideas on facing facades, landscape and interior decoration.

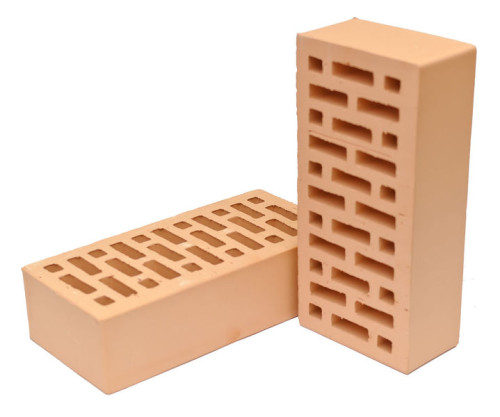

Clay bricks also differ depending on the scope of application and structure. So, the ordinary brick is needed for the construction of walls, and facing - for decoration. The structure distinguishes hollow and full-scale products. The dimensions can also be different: single has the side 250x120x65 mm, one-time in the width of a little thicker - 250x120x88 mm, and double and more - 250x120x138 mm.

Full brick has a solid structure without voids. From it are building strong bearing walls, columnary structures, vaults, pillars, it is involved in the arrangement of the ground floor floors, basements and foundations. Hollow, on the contrary, has inside the cavity of various shapes, which after laying are filled with insulation. This reduces the load on the foundation by reducing the weight of the wall itself, and make the house warmer.

Calculation of bricks for the construction of the house should be made after selecting the main type of material. And if the burned brick is distinguished by universality and is quite expensive, then silicate (lime) has a lower price, but it cannot be used for the construction of foundations and other supporting structures. Despite the low strength, silicate brick has its advantages - it is easy to install, keeps warm well, protects against noise. If competently combine the use of clay and lime materials, you can save on purchasing. So, from the burned brick you can build all the bearing walls, and silicate to put on the creation of interroom partitions.

Silicate bricks, like clay, can be with voids without. The hollows are characterized by less weight and thermal conductivity, so they are actively used for the construction of warm residential buildings. Full-scale products have a wider color palette - they can be white, yellow, orange, coffee colors with milk, even black or blue.

Properties of bricks

When choosing bricks, you should pay attention not only to its cost and dimensions, but also for some properties. Water absorption, strength and frost resistance plays a special role. The ability to absorb water is measured as a percentage. The rule for brick is from 6% to 16%. It is clear that to build the external walls at home it is better to choose a material with minimal water absorption.

Frost resistance directly depends on the water absorption of bricks - the lower, the higher the frost resistance. Unit of measurement - cycle (denoted by the letter F). The outer walls are recommended to build from ordinary brick with frost-resistance F25. For decoration, choose a facing brick with frost-resistance F50 (because it is twice thin).

Strength is indicated by the letter M and a digit that indicates which load is able to withstand a brick to 1 cm². The greater the number, the hardest material. The minimum indicators of M75 and M100 are suitable for the construction of a low residential building a maximum of 3 floors. More durable products with marking M150 and M175 are suitable for laying the foundations and construction of the ground floors.

Important: marking is one and for hollow, and for full-scale bricks. This means that if M100 is written on products, then they will be able to withstand the same load regardless of the structure. In addition, the strength of the masonry depends not only on the brand of the product, but also from the solution used and the thickness of the seams.

To pay attention to when choosing a brick:

- Perforated products are designed to build light structures that will not experience loads - interior partitions, outdoor cladding or to fill opening under the supporting structures. Thanks to air emptiness, the insulation of the room is enhanced. The maximum allowable diameter of the holes is 16 mm.

- Before buying, inspect the bricks for the presence of defects - chips, cracks, faded corners, etc. The permissible maximum is 2 minor defects per unit, and the angles can be deceived no more than 10 mm, and cracks are in length not more than 30 mm. But these rules concern only ordinary bricks - no flaws can be on facing.

- Pay attention to the mass, dimensions and marking of products. In the dried form, any brick should weigh no more than 4.3 kg.

- Environmentally friendly - this parameter is also indicated in the certificate and should not be more than 370 BC / kg.

- Features of storage and transportation - Naturally, immediately put the entire volume of bricks in the case will not work, so the repository should be organized for it. It can be any room with good ventilation, protected from bad weather. Store bricks follows in stacks, making ventilation gaps in masonry. The image below shows how to store building materials:

- As for transportation, the bricks should be transported on special pallets, but at this moment we will dwell in more detail below.

- Be sure to check the documentation - the brick must be certified or have a passport with an indication of all technical characteristics and manufacturer factory.

- Check the brick to marry several pieces in each batch. Signs of defective products are described in detail below.

How to determine marriage

In order for the creation of bricks for construction, it does not turn into an empty spending time, it is necessary to immediately make sure that the appropriate quality of the acquired material is required. Otherwise, then you have to calculate how many bricks should be purchased instead of unsuitable. A complete list of brick requirements is outlined in GOST 530-2007, but if briefly, the product brand should be no less than M100, and frost resistance is not less than F35.

Signs of illiquid products:

- Squares on the front surface, stains and cracks, noticeable from a distance of 10 m with natural lighting.

- Non-compliance with standard dimensions (permissible deviations not more than ± 4 mm in length, ± 3 mm wide and ± 2 mm in thickness).

- Ceramic brick is also considered a ceramic or inone of the ceramic brick. To determine whether the party is made qualitatively, take one brick and split it. The ringing when hitting and the saturated color of the core indicates good quality. If you heard a deaf knock, and inside the brick turned out to be dull, most likely, he was not finished into the oven. In this case, the material will strongly absorb water and cracks at the very first frosts.

- The checked brick, on the contrary, outside is too dark or even blackened. But there is one building trick - if you split the brick, and inside it turned out to be darkened, then you are extremely lucky, because according to experts, such material will be much stronger than ordinary brick, burned in ideal conditions.

- If the ceramic brick is whitish and row, it means that there is a large number of lime inclusions in its composition. Unfortunately, it is impossible to completely get rid of them in the production process, since filters are not missing on the factories that do not pass only large fractions. If a large piece of lime-based material got into the brick, it will absorb moisture and swell, with the result that the product is cracking. If the depth of chips from lime is less than 6 mm, the bricks go on sale.

- Solutions are the most unpleasant phenomenon when working with bricks. This is not exactly marriage, but still can spoil the appearance of the material. Solutions (from the word "salt") appear on bricks as a result of penetration of groundwater salts, a masonry solution or air. They look in the form of ugly whiten spots and drills, which are formed after the completion of construction, so it is impossible to prevent or predict their appearance. To reduce the risk of heights, you can not work in cloudy weather, do not smear the solution on the outside of the masonry and cover the incomplete sections for the night with a polyethylene film so that Rosa does not get to the brick.

Masonry solution

So, when you learned everything you need to calculate the brick and purchase it in full, another moment occurs - the solution for masonry. After all, the wall consists not only of bricks - 20% of the volume falls on the solution on which all elements hold. Therefore, I will postpone the calculation for another while and let's talk about what glue bricks.

Almost always for masonry bricks make a classic cement-sandy mixture diluted with water. For this, cement is mixed with sainted river sand in a 1: 3 or 1: 4 ratio and diluted with water to the desired consistency. Depending on the proportions, the plasticity and strength of the solution differs. To increase the plasticity, builders add lime, natural clay or synthetic plasticizers. By the way, plasticizers are extremely popular. They can be used for different purposes up to the point that with such a solution can be operated in a minus temperature.

Another important point is the mobility of the solution. For each method of masonry, it is necessary to make a mixture with a certain mobility. It is possible to determine this indicator by immersing the reference cone into the solution and looking at its precipitate. Thus, the hollow and perforated brick can be put on a solution with a sedimentary cone 7-8 cm. With high mobility, the mixture will quickly fill all the holes in blocks, which will negatively affect the thermal insulation characteristics for which they are valued. The solution for full-scale brick should be more liquid and to give a sediment of a cone at 9-14 cm. If it is too thick, then over time cracks.

The quality of the solution depends not only on the plasticity but also homogeneity. To achieve optimum consistency, you must purchase the sifted fine sand and sift it yourself. If the mixture is cooked properly, enough thin layer to securely hold the bricks across the adjacent surface.

transportation of bricks

As promised above, a few words about the specifics of the material transport. The purchase price includes the brick delivery to site, therefore this factor must be taken into account in the calculation.

Brick refers to a rather expensive material, particularly when it comes to full-bodied pottery. Calculate the required amount, add to it 10% in case of a fight or repair in the future. To minimize the number of broken items, it is necessary to carry bricks on pallets in their original packaging or containers.

If transport takes place on pallets, bricks should be placed with a special bandage "herringbone", that is inclined toward the center from both edges at an angle of 45 °. Thus they can be transported in conventional vehicles without additional flanges. Pallet size 52h185 200 cm can accommodate ceramic bricks pallet 50h185 cm - 450 silicate bricks.

calculation of brick

So, we told all you need to know for the proper calculation of the brick house. Last warning - always remember that in the joints accounts for about 20% of the total volume of masonry.

Here is an example calculation of brick house 10x10 m.

Progress:

- The first thing you need to know the total length of the exterior walls. Since in this case the house completely normal, he has all 4 walls of 10 m each, for a total of 40 m.

- Ceiling height will be 3.1 m, therefore the height of two storeys - 6.2 m On the basis of available data, it is possible to find the total area of \u200b\u200bthe exterior walls.:

S \u003d 40 * 6.2 \u003d 248 meters. - Of the total area to be subtracted land area allocated for windows and doors, because they are filled with bricks. For our house is 38 m², so 248-38 \u003d 210 m².

- Walls are stacked in masonry 2.5, therefore their thickness be 68 cm. First, dual clutch will be performed from a single common brick, and 1 row of stacked single facing brick. The most common method of construction is to lay a single brick, then the insulation and cladding. The desired amount of material can be determined according to the table below. Calculation of bricks on the house is as follows: 21 * 210 \u003d 10 710 pcs.

- We find the required number of ordinary single bricks for the walls: 204 * 210 \u003d 42 840 pcs.

Now you can compare this data with the value of the materials and find out how many tools will go to purchase and how much will it take a solution. Consider that these calculations do not include interroom partitions. Proper expenditure planning is the key to economical construction and prevents from unforeseen spending. For greater amenities, you can use the Calculator for calculating the brick online.

As you can see, it is not difficult to calculate the required number of building materials, the main thing is to be able to understand the varieties of bricks in order not to guess with the quality and durability of the future building. The devil is known to be hidden in the trifles, so before such a responsible case, as the construction of a residential building, it is better to deal with theory.

![image_31-01-2014_ [1391178626]](http://dachnaya-zhizn.ru/images/dacha/image_31-01-2014_1391178626-500x375.jpg)

Start a discussion ...

Start a discussion ...