To ensure a convenient entry of a car to the site and at the same time reliable protection, it is necessary to install the gate. It used to be very popular with the designs of a swing type, since it was worth it inexpensively, and it was easy to make them with their own hands. However, there are one significant disadvantage among such gates - they require a lot of free space for the unhindered movement of the sash. It is this factor and served as a impetus to the creation and development of a retracting gate. They save the mass of space, are convenient to use and durable. The cost of such pleasure is still higher than that at the swollen gate, but if you figure out the theory and collect a rollback gate with your own hands according to drawings, you can save significantly.

Classification of retractable gate

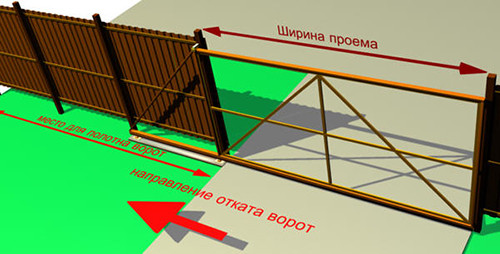

There are several types of retractable gates, each of which has its own design features. However, regardless of the configuration, each of these species has advantages characteristic of this type of structures - saves free space, easily controlled, is distinguished by durability and unpretentiousness. The only condition that is necessary for the installation of a rollback gate is a sufficient length of the side of the section. The length should be such to accommodate two lengths of the gate section with a margin.

So, what kind of types of gates are:

- Console - guide is fixed at the bottom of the portal canvase. When driving, such a gate do not get to the ground and at the same time do not have restrictions at the top. Today it is the most popular design that can compete on demand except with a rollback gate on wheels.

- Suspended - the guide is placed above the opening, while the gate is in suspended on special roller carts. Typically, such structures are not used in the private sector, but to equip industrial and warehouse space.

- On the wheels - the guide rail is installed in the opening, and special wheels are attached to the bottom of the sash. The rail is mounted directly on the foundation of the gate. The main disadvantage of the gate on the wheels is the need for their regular cleaning - if a stone falls into the rail, the branch, the bump, it will be filled with ice or mud, the gate will not work.

The cantilever gate, however, is considered the most convenient, since such a design does not constitute restrictions on top, and even very high transportation can be driving to the site. Suspended gates of such privileges do not give. At the same time, it is very important that the mechanical component of the console gate is entirely outside the entrance space, and therefore does not need regular care and cleaning, as the gate on the wheels.

Managing the retractable gate can be carried out in manual or automatic mode. To implement the latter, you will need to purchase special equipment (drive, photocells, radio receivers, sensors, etc.). Automation for the retractable gate is much more expensive, but to open them, it will be enough to click the button without leaving the house.

By the number of flaps, the sliding gates are the following types:

- Monoshirma - Gate consisting of one solid sash, based on a mortgage detail on the foundation. This design does not need a drawing on the tops of the columns and moves only one way. Monosirm can only be installed if the height of the web does not exceed 2 m. This option is perfect for the private sector, parking lots.

- Bivalve - consists of two scenery of the same sizes that are synchronously moved into different directions. As a support serve two foundations - one on each side of the gate. This design needs to install the upper beam, which directs the movement of the canvases. Such an option is relevant for high height hangars, parking lots of trucks and strategic and industrial facilities.

Gate do it yourself

Before embarking on the gate assembly, it should be sorted out, from which they can be built and which scheme take advantage. It is important to understand that the gate should not only be durable and durable, they must be harmonized with an exterior and landscape. So if the fence around the site is built of stone or wood, then the gate is better to make wooden. Also a beautiful combination gives a brick with a forged metal. In order to simplify the most easily and reduced the cost, you can build a gate and a fence from the professional flooring.

Important moment: Try to choose the material for the construction of the gate with the smallest mass - the less the gate will weigh, the smaller the load they will be given to support.

In addition to the main material you will need accessories and tools: welding machine, wrench, Bulgarian, screwdriver, etc. It is very important that the gate is welded without the slightest distortions, so you need to work on a flat site. It is also recommended to prepare goats or a prefabricated workshop, the dimensions of which include the dimensions of the interface of 1 m from all sides.

When drawing up a drawing of a retractable gate, it should be borne in mind that the surface above the movable part of the design should be strictly horizontal, the distance between the surface of the earth and the lower line of the gate must be at least 4 cm, and the movable scenes should be longer than the opening of exactly half.

Below are examples of the retractable gate schemes that you can use as a basis for designing your own structures:

Gate hardware accessories

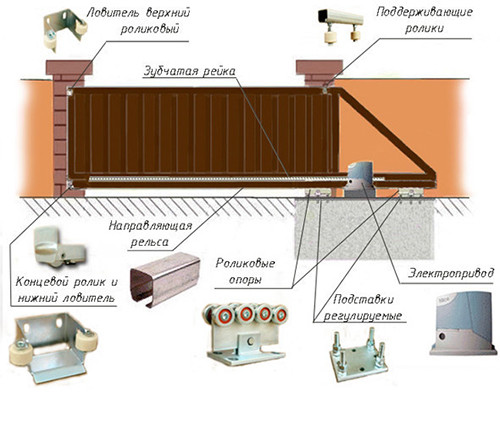

The choice of components for the retractable gate depends on their dimensions, weight and design features. The basis of any gate is a certain set - details that ensure the stable operation of the assembled product.

In the market you will find several standard sets:

- the minimum set for the gate with the width of the opening up to 4 m and the total weight of up to 400 kg;

- the average is a set of elements for a gate with a width of opening from 4 to 6 m and a total weight of up to 600 kg;

- the maximum set for the gate with the opening of 6 m and more and the total weight of over 600 kg.

To select components for a sliding gate, first of all, it is necessary to calculate the load on the accessories. This can be done, knowing the size of the sections and the mass of the material from which they will be made. For a private house or cottage plot, the gates with opening up to 4 m are best fit, and therefore a small kit of fittings. Often the canvas of such gates are covered with sufficiently lightweight materials: siding, professional flooring and so on. If you are going to install the gate with open 4 m, but you want to decorate their wrought elements, heavy board and other similar materials, the total mass will increase significantly, and the average kit with enhanced fittings will be needed.

How to make a cloth

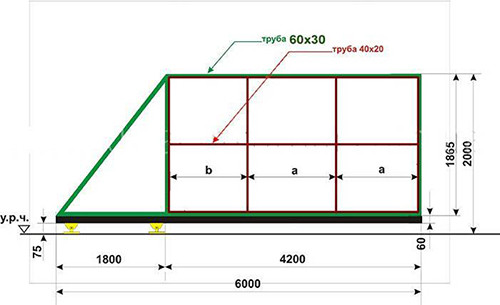

To fully understand the principle of installing a rollback gate, it is necessary to consider in detail all the stages of creating a design, starting with the assembly of the canvas. For example, we consider the option with an opening of 4 m wide for a canvas in 2 m with a road lumen of 75 mm. The upholstery of the canvas will be from the profile, since this is the most popular option. The distinctive feature of the presented gates is the presence of a counterweight - part of the canvas that does not overlap the opening. It is usually half a half of the width of the opening, that is, in our case - about 2 m.

The framework will be made of steel pipes:

- 60x30 mm - 16 m of pole 3x6 (6 m, 4 m, 2 segments of 1.85 m, 2.7 m);

- 40x20 - 20 m of pole 4x6 (3 segments of 4 m, 4 segments of 2 m);

- guide - 6 m.

Over the entire length of the tire, weld the pipe 60x30 with a wide side of it, retreating from the visible end of 300 mm, to then put a vertical frame of the frame. Make welds 50 mm with a distance of 40 cm on both sides. Perpendicular to the tire in the width of the gate (side 4 m) brew pipes with a length of 1.85 m. If necessary, cut the ends of the pipes and connect them with a segment of 4 m (while we work only 60x30).

Important moment: in this stage, swipe diagonal, mark the size and adjust the skews until the wedroom is detected.

When you adjusted the windows, check the pipe 2.7 m from the free end of the guide to the top corner of the frame. Cut it and install it on the tape, after which you can brew all the joints.

Spice the inner part of the frame on 6 identical rectangles and decompose the pipes with a cross section of 20x40. Statches them in place and cut the grinder. You need to welcome these pipes with a narrow side to the frame, and therefore prepare the lining 20 mm in advance. They will allow you to leave the desired amount of free space to the edge of the frame, so that then insert the professionalist there. Grab and fuel internal frame pipes.

Be sure to work out all the welds. To do this, you can use conventional emery paper, but the grinding machine or the disc will save time and strength. After grinding, fill the seams by the disk of the "petal" for the grinder. Remove the scale and metal dust, wipe the frame with a ragine dipped in the solvent, and cover the pipes of anti-corrosion paint.

Useful advice: For painting a metal frame, it is best to use car enamel or nitroemal. These compositions quickly dry out and are characterized by good protective indicators. For more reliable protection of the pipe fitting, fill with silicone sealant.

When the paint is driving, it will only remain to strip the frame. To do this, make markup on the professional foots in accordance with the sizes of the frame, cut them out and attach them to the internal frameworks (20x40) pipes with wide hats or rivets. To cover the gate, you can use many building materials: panel panels or sandwich panels, grille, steel rail, block mobile phone or polycarbonate. In any case, the principle of assembling the frame will remain the same.

Mounting the gate

To put the gate, you need to get a strong mortgage part (usually this is a 200 mm channel). It is firmly fixed to the foundation that takes the whole severity of the gate. The foundation should be from the side of that post, where the canvas will go. In our case, the foundation is two meter piles installed on the edges and soldier. Scarlet performs a pillow function for a mortgage part.

Useful advice: It will be more convenient and safer to work if you cook the frame in advance and immediately combine it with a chaserler in a solid design. Before pouring concrete, check the horizontal part of the mortgage part several times.

To facilitate the process of installing a channel, on both sides you can spew the handles. When the concrete solution is completely strengthened, along the edges of the mortgage part in accordance with the axis of the gate of the gate, make roller carriages from the kit of fittings. Attach the rollers, putting them on the bolts.

The support pillars strictly vertically attach additional pillars - pipes with a cross section of 60x80 mm. They must rise above the post by 10 cm. To the false pole installed near the foundation at an external height, grab the supporting bar with the rollers, to the second pole from above and bottom to attach the trap.

Important moment: any welding manipulation until the adjustment should be performed point, not welding, but "grabbing".

Install the cloth so that the bottom carriage rollers enter the bus, and the upper pipe of the 60x30 rolled between the roller elements. At this stage, it is better to enlist the support to mount the bar with the supporting rollers at once during the installation of the canvas itself. Attach the end roller, guided by the instructions attached to the kit, and spend the test test. Only after testing the work of the gate, you can make adjustments and fix all the details.

Useful advice: Rollers are better to abundantly lubricate with solidol to make the movement of the gate soft and smooth.

We reviewed the installation process of a non-automatic design, since the installation of electronic equipment requires special skills and knowledge that you will not master by reading one article. The automatic drive for a sliding gate will allow you to control them remotely. Such a gate is very checked, however, you can save a significant amount if you build them with your own hands, and you will order automation from specialists. With careful operation and timely maintenance, the slotted gates of the console type will serve at least 10-12 years.

Finally, we suggest watch a video about the skate gate and the features of their installation:

Start a discussion ...

Start a discussion ...