When used for heating a home or apartment of the instruments, the principle of operation of which is built on burning solid, liquid or gaseous fuel, one of the most important parts of such a system is chimney. It is necessary to withdraw from carbon monoxide, which is fatal for the human body. That is why the safety of people in the premises of people depends on the correctness of the design and operation of the chimney.

The designs of chimney

There are several types of chimney designs. The selection of the system installation project depends on several conditions:

- Project building. The location of the rooms, the place where the heating device will be installed, the complexity of the facade, the roof configuration, etc.

- Type of heating device. Configuration of the outlet, fuel type, presence of forced ventilation.

- Quite often in the technical specification to the heating device and manuals for it, the manufacturer's manufacturer indicates the parameters of the safe operation of the chimney.

Types of chimney

At the place of its location, chimneys are divided into the following types.

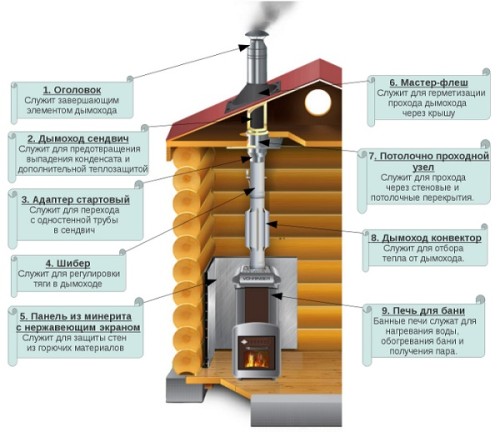

Internal. As a rule, such systems are mounted if they are an additional heat source for heating the room. The fact is that the temperature of the exhaust gases from the heating device remains rather high and can be used to heat the room. Usually, internal chimneys are equipped for removal of gases from a fireplace available in the middle of the house. They are built out of brick or stone. Recently, stainless steel pipes with special heat sinks are often used for internal chimneys, which allow you to obtain heat from the discharge gases. For a more beautiful species, the chimneys from a stainless steel are sewn with drywall and look with decorative stone. Then the fireplace looks very original.

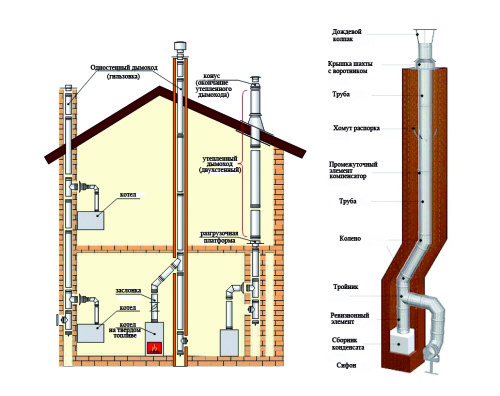

Exterior chimneys. Such types of systems are most commonly used to remove gases from gas and solid fuel boilers installed in separate rooms that have one outer wall.

Such chimney is more practical than domestic for several reasons:

- Security. In case of damage to the chimney, the risk of carbon monoxide emissions is reduced inside the room, which can lead to tragedy.

- Also, the absence of chimney indoors reduces the likelihood of a fire in the event of its strong overheating. For external chimneys, there is no need for a device of fire islands in overlaps if they are made of wood.

- Less costs of purchasing and installing outdoor chimney. Due to the fact that the external systems reduced safety requirements, the cost is much lower, and the installation is simpler. In addition, it is worth noting that the temperature of gases after modern boilers with high efficiency are not too high, so it is unlikely to go through the premises. If there are simple tools and elementary skills, the installation of a similar device can be carried out for counting hours.

Types of external chimneys

Exterior chimneys are:

- Steel.

- Cast iron.

- Stainless.

- Ceramic.

- Sandwich pipes.

The first material is the easiest option. It is usually used for the construction of heating systems in the baths, garages and utility rooms, that is, where the heating device is not constantly used. The use of steel, like iron pipes for chimneys, is not too suitable when external installation. The fact is that under the influence of humidity, which is guaranteed to accumulate on its surface, such a pipe is quickly rust, which leads to the destruction of the metal and the appearance of corrosive holes, which reduces the chimney thrust. If you cover such a chimney of paint, then it must be a special, not fearing high temperature, and this material is not cheap. In addition, the chimney of steel requires welding, and these are additional costs.

Chimney Sandwich Outdoor It has such a name, because its structure is similar to a popular sandwich. In the context, such chimney consists of two pipes. The inner performs the role of the smoke channel directly, and the second is a decorative function. There is a layer of insulating material between the two pipes. Due to this, the outer surface of the chimney is not cooled, which prevents the condensate accumulation inside the system. That is why when installing the outer sandwich chimney, there is no need to install the condensate collection at the bottom of the chimney.

Chimney from stainless steel. Such chimney is the most optimal option for external use. This material is not subject to corrosion, easily mounted without the use of special means. The advantage of such a chimney is that it has a small weight, and in effect, does not carry an additional burden on the facade of the building. Also indisputable advantage is the price of such a system. Their production can be adjusted in any tin workshop without the use of expensive technologies. To mount the chimney of stainless steel, the owner of the house will be enough perforator, several special clamps (usually come complete with chimney), screwdriver and a set of fasteners.

Ceramic chimney. Such systems are relatively expensive. With all its advantages, and this is first of all, a long service life, they are quite capricious in the installation. As a rule, they are assembled indoors. The construction of a ceramic chimney requires the installation of a special box of slag concrete blocks, within which it will be installed. If such a system is built outside, then it is necessary to make aware that construction works on the arrangement of an additional box can not be avoided. That is why ceramic structures are very rarely used when installing an external chimney.

Metal chimneys. Steel grades in their production

When using stainless steel for the installation of external chimney it is very important to choose the properly of steel and metal thickness correctly. According to EU standards, the following steel grades are used to produce external chimneys:

- 316, 316L - This brand, thanks to the additives from nickel and molybdenum, has increased acid resistance, therefore it is less corrosion, which in turn positively affects the wear resistance of the entire system. This is especially noticeable when using liquid fuels for which it is intended.

- Brand 304 differs from the previously low content of alloying substances, so it is not so good for liquid fuel, however, wins in the price equivalent.

- 409 - This brand due to the content of titanium in its chemical composition has high strength, which favorably affects work in high temperatures. The chimneys from the stainless steel of this species are ideal for working with solid fuel, such as coke or anthracite. However, this steel brand has low acid resistance, which does not allow such chimney to work with boilers on liquid fuel having a high content of sulfur.

- 321, 316 Ti - the most common stamps of steel. The high content of titanium, nickel and molybdenum makes them almost indispensable for the chimney of stainless steel. Excellent plasticity, thermo- and acid resistance made data from brand leaders in this industry.

Required steel thickness in the production of chimney systems

In addition to the steel grade, it is necessary to pay attention to the thickness of the sheet, from which the chimney of stainless steel is made. The sheet, the thickness of less necessary, can during operation to give proper, which will cause a decrease in thrust in the chimney. The sheet is greater thickness than the regulatory, on the contrary, will be an additional load on the facade of the building, and also loses price.

According to the regulations of the European Union, the following thickness indicators are adopted for the installation of external chimneys from stainless steel:

- For heating boilers, which operate on solid fuel, the thickness of the wall of the outer pipe of the chimney should be at least 0.5-0.6 mm.

- For boilers on liquid fuel - not less than 0.8 mm.

- For gas heating devices - at least 1 mm.

Installation of outdoor chimney for boiler

So, we figured out the features of the materials for the device of the external chimney. The most optimal system is the stainless pipe of the corresponding steel grade and wall thickness (depending on the type of fuel on which the boiler works). Immediately, we note that if the might-fuel boiler, the wall thickness and steel brand is considered to fuel with the highest combustion temperature.

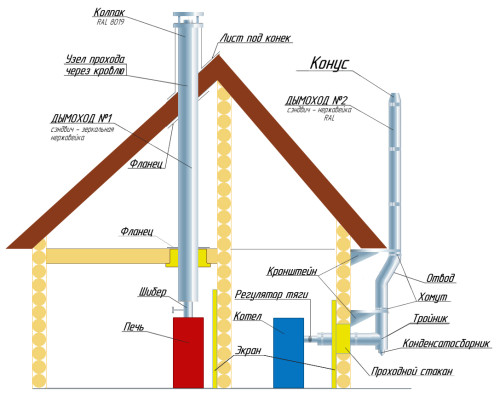

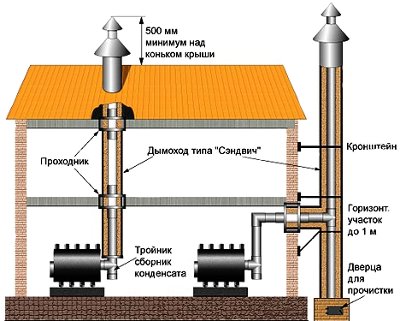

An important condition for mounting the outer chimney is the lack of horizontal transitions. As a rule, it is in them the greatest amount of soot and condensate that impede the normal thrust.

Also very important is the distance from the pipe to the ridge of the roof, which affects the height of the chimney. The closer the chimney to the top of the skate, the greater its height.

Basic requirements for how to make an outdoor chimney:

- Installation work It is necessary to produce "bottom-up", inserting each subsequent section inside the previous one. The depth of the joint should be at least half the outer diameter of the pipe.

- When installing the outer chimney, with your own hands for sealing, each joint is processed by a special sealant and clamping a clamp.

- Walls, along which chimney is laid, should be from non-combustible materials. Otherwise, a technological gap or a gasket from non-phase material is required.

- At a distance of 1-1.5 meters, the pipe plot is attached to the wall of the house with a special bracket. Transitions or other structural elements are attached separately.

- It is necessary to eliminate the contact of the areas of the outer chimney with electrical wiring or gas highways.

- When installing the external chimney, overlooking the outer wall, it is necessary to provide for an audit window or a removable part for maintaining the system.

The phased order of the decoration of the chimney:

- Take a hole in the wall. It must be located at a distance of at least 50 cm from the boiler itself.

- Fix the fasteners that will serve as a support for the installation of chimney. Fasteners for the pipe are installed in a step of no more than 90 cm.

- Connect the bottom of the pipe to the boiler.

- The upper part of the chimney is laid out.

- Mount the condenser.

- Secure chimney.

Start a discussion ...

Start a discussion ...