You have a cow, and not even alone, and you find it difficult to implement milk? We advise you to process it on cheese. True, cheesecake is a cotton one, you can even say - cannon, but what wonderful products will be on sale or just for your table!

You have a cow, and not even alone, and you find it difficult to implement milk? We advise you to process it on cheese. True, cheesecake is a cotton one, you can even say - cannon, but what wonderful products will be on sale or just for your table!

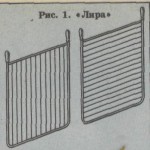

It is necessary to prepare thoroughly, first of all stocking inventory, so as not to run in search of it when the milk will already be quas. It will take you the syroemic and tel - aluminum, enameled or stainless steel container with a capacity of 50-100 liters, and better two - one is slightly smaller to fit inside the other. Lira is also needed for

Mold and press cheese in special containers. They can be of a variety of materials, only galvanized tin or steel without protective coating is not suitable. For cheese in the form of Brousa, adapt a special wooden box (Fig. 3). At the bottom and on the sides of it in checker, 10-20 holes with a diameter of 3-4 mm are drilled. For round cheeses there is a good plastic form (Fig. 4), but you can make it and woven from willow. Pressing the product is necessary under load, so the covers will be required to tanks, better wooden, slightly less internal sizes of forms. In addition, prepare the tank of the appropriate capacity for the ambulance, the thermometer (better than alcohol), napkins from the cloth of rare weaving. By the way, the entire inventory is soaked, boiled and dried in the sun. So, the inventory is ready, now it is necessary to take care of Zakvask,

The easiest way to take prostrip. However, it happens different, and only experienced cheese can pick up the accurate regime of the fermentation. From the factory (laboratory) Rodskaya work easier and easier, try to purchase it on the nearest cheesery or dairy factory. If it is dry Okvaska, it first get the so-called maternal one, and from this prepare a worker. Good "cheese grain" is formed when making calcium chloride and pepsin, which are sold in pharmacies.

The easiest way to take prostrip. However, it happens different, and only experienced cheese can pick up the accurate regime of the fermentation. From the factory (laboratory) Rodskaya work easier and easier, try to purchase it on the nearest cheesery or dairy factory. If it is dry Okvaska, it first get the so-called maternal one, and from this prepare a worker. Good "cheese grain" is formed when making calcium chloride and pepsin, which are sold in pharmacies.

To prepare a workshop, fresh or solid milk boiled half an hour or pasteurize at 90-95 ° for an hour and cooled in the same dishes to 30-32 °. Then they bring into it or a factory starter, or a prostropriety - approximately 2%. Each time part of it is left until the next "cheerful" day. However, 1-2 times a month, Zavskaya is changed, as bacteriophage can develop in it, 'virus that will suppress lactic acid bacteria, and good cheese will not work. Slow belling of milk will be slow to change the break.

Finally, you can directly proceed to the manufacture of cheese. Technological techniques can be different.

According to one of them, the evening fishing milk is put in a cold (5-10 °) place until the morning. Then the remaining layer of fat is removed. (It remains in milk 1.3-2.5%.) This low-fat product is mixed with a fresh pointer (you can with low-fat low milk) and the Morning Wood's milk in a 2: 1: 1 ratio. The mixture is heated to 26-28 °, stirring, so as not to the burden, and poured into the source. On a bucket (10 L) of the dairy mixture, 1.5-2 glasses of frisks and 1 tablespoon of a 40% solution of calcium chloride are brought. There is also a half-table of the substation of pepsin. For this, it is divorced in 1 l boiled and cooled to 30-40 ° water or sour serum 1 g - on the tip of the knife. The remaining solution can be stored for several weeks in the refrigerator.

The mixture is still stirred for 3 - 5 minutes and leave in a warm place to form a clutch. Make sure that the temperature does not fall sharply and to the end of the shutter speed was not lower than 25 °. When a dense clush is formed, its cooled top layer is approaching a large spoon and turn over. The inverted bunch gives to stand 10-15 minutes. Thus, leveling the temperature of the whole mass, delay the transition of fat and protein into serum. Now it will be needed "Lira *. At first, act with vertically strained strings, and then with horizontal. The raw mass is cut by cubes with an edge of 8-10 mm. The cut bunch is left for 5-10 minutes, so that the serum is fully separated, and then the wooden spatula is gently mixed with 3 * -5 min and 1-3 minutes defend. The cheese grain is compressed, settles on the bottom of the tank, after which about a third of the serum is selected, and the remaining mass is again stirred for 15-20 minutes so that no lumps remains.

Now the above-mentioned serum is heated to 55-60 ° and contribute to the syroemic and tel, splashing or pouring it onto a wooden spatula. The temperature of the cheese mass should increase to 38-40 ° for another 15-30 minutes, while "grain * will not be dense and enough to the touch.

Everything. You can proceed to molding cheese. Forms are lined with a napkin from a cloth of rare weaving and laid in it a colander or a silica raw grain. Above the mass is covered with a second napkin, lid and leave for half an hour to pressing and dehydration,

Then they put the load at the rate of 3-5 kg \u200b\u200bper 1 kg of cheese mass and withstand another hour.

Do not forget to salute cheese. To do this, it is removed from the forms or rub the salt, or they are lowered into a strong warm brine (18-21%) by 5 - 7 hours depending on the magnitude of the heads.

A day later, the cheese can be served on the table. Store it in the cold no more than a week, the UPA forged into polyethylene packages, paper, cardboard co1 timid or wooden boxes.

According to the second method, the cheese of the type of Adygei is obtained. The milk mixture is prepared, as mentioned above, heated to a temperature of 93-95 ° and with continuous stirring, cautiously thin flowing poured with acid serum (8-10% of the amount of the mixture). At the same time, flaky protein bunches are formed. The cheese mass is left for 3-5 minutes, after which the coiled coils are laid out in forms. Serum is filled through a napkin to separate the remaining portion of the clock. Mass leave for self-resistance and cooling for 10-15 minutes. During this time, the cheese turns over once. The compressed bunch is rubbed and withstand 10-20 hours at a temperature of 8-10. During this time, two times turn over.

In such a cheese, it is good to add greens, spices, other fillers.

According to the third method for cheese, a milk mixture of solid, skimmed milk or smells is prepared. It is heated to 32-41 "and for 30-40 minutes, they are coincided with pepsin, extractor from beef or lambs of Sichnov or factory leaven. (The clot is ready when a transparent greenish-yellow serum is released when it is cut, and the edges of the cut indicate the corners.) Make a raw grain with a size of 10-20 mm and leave it for 5-7 minutes, then be carefully laid until abundant serum. Next, everything is transfused into a wide pelvis, heated to 92-95 ° and at this temperature for 2- 4 hours, moisture is evaporated, followed so that it does not fit. The thickened mass is solid to taste, lay out in glass jars, clay pots or enameled tanks. While it is hot, you can add additives - cutoff, cilantro, garlic, etc. Then the tanks with cheese are collapsed into glass jars and cooled at 10 -15 °. In such conditions, the product is stored for two weeks, if you pour the surface of the cheese mass in the cans with oil or fat, then ft longer.

Mass after thickening can not be packaged in banks, but to suck in draft. Then, crying into a handful, to blame the mass between the fingers. The resulting cheese lumps decompose on the sieve and dried with solar weather day-two. Dry cheese is collected in paper bags, linen bags, cardboard or wooden boxes. In a cool place, such cheese can be stored for several months. This product is a good additive to vegetable dishes, macaronam, in soup or for filling of pies. Before use, dry cheese is restored by mixing with a small amount of water.

Start a discussion ...

Start a discussion ...