Metal forging is one of the most ancient ways to give the interior of the house of sophistication and style, make it more attractive and unusual. And in order to make a cold forging, it is not necessary to be a blacksmith. In this article we will tell you that it is a cold forging and how it is carried out.

Features of cold forging

Instruments:

- hammer;

- welding;

- nutica;

- snail;

- lantern;

- wave;

- twister;

- machine for rings.

Materials:

- bars;

- sheet metal;

- round and profile pipes.

The main advantage of cold forging is the lack of need to use Horn. Metal for processing heated does not have to. The whole process is a legend of the desired shape of the workpiece, for which it can bend, press and weld. To do cold forging, you do not have to equip a big workshop, and the lack of the need to work with open fire and hot metals makes the process much easier and safer.

The only negative is to work with already prepared blanks, which are a kind of semi-finished products, and if you allow an error in processing, most likely to fix it will not be possible. Not always, but often spoiled blank is no longer suitable. In addition, you need to comply with security. Especially when you are engaged in welding individual elements with each other.

Cold forging with their own hands requires care, caution and understanding of the subtleties of the process. Initially, it is necessary to familiarize yourself with the properties of the metals used, as well as understand the specific intricacies of their processing. There is a list of technological techniques that are used in operation.

Metal selection

You need to be prepared for the fact that even the cold forging will require you a lot of time and strength. And the complexity of processing is often depends on the selected metal. The main indicator in this case is plasticity. It directly depends on the simplicity and breadth of the workpiece processing. Plasticity and strength are tightly intertwined with each other. And than one above, the point will be below. That is, the metal with a high level of plasticity will not be durable and strong. And vice versa. Therefore, when you choose a cold forging material, you already need to know its characteristics and be prepared for the time consuming process.

In modern decorative forging, a number of metals are used: steel, brass, copper, duralumin and various types of alloys of these metals. For cold forging need metal, which is easy to process, plastic and supportive. It is easier to work with it, and the result will get better. To familiarize yourself with the list of suitable materials. More details, you can contact the march of steel and alloys, where there is a complete list of all materials used in modern forging, their characteristics and key features.

Selection Tips:

- The most forging metals are copper alloys. However, the cost of blanks is quite high. To save, you can use ferrous metals that cost cheaper, but have more difficulties in processing.

- If you choose from ferrous metals, always pay attention to the carbon content. It is desirable that its amount does not exceed 0.25%. A greater number greatly worsens the plasticity of the metal and makes a lot of work.

- In the metal should not be (or be the minimum number) of harmful impurities: phosphorus, chrome, sulfur, molybdenum, etc.

- Try to choose to always focus on the Steel and Alloys directory to find out how much carbon will be in one or another workpiece, and understand how difficult it will work with it.

To date, the heavy industry has leveled the need to make workpieces with their own hands, which is a big plus for us. In your homely forge, you can apply the elements ready for processing. Today, a wide selection of such materials is available: profile pipes, rods, round pipes, metal sheets, etc. In this case, you can choose the appropriate size and shape to simplify your work.

Specific use of tools

Naturally, it will not be possible to do with prickly means. Therefore, we advise you to get acquainted with the list of tools for cold forging:

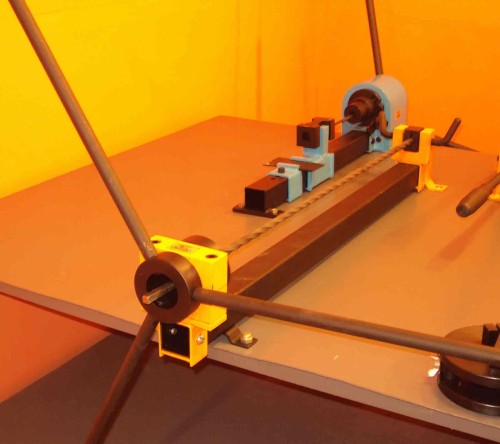

- Gnut. One of the main tools, allowing to bend the workpiece under the angle you need, without making great physical efforts. In addition, with it, you can create arcuate elements with the desired radius.

- Snail. Allows you to make spiral elements that are often used in decorating. Its main property is a template. That is, the billet will bend in a certain radius, gradually narrowing. But if desired and the need, the template can be changed to pick up a more suitable radius.

- Lantern. It is designed to create lantern elements from the rod.

- Wave. When the rod metal passes through the machine, it acquires a wavy neat shape. You can adjust the height of the waves and the indentation between them.

- Twister. The tool twists the workpiece by its axis. You can also adjust the number of revolutions to get exactly the result you need. According to his principle, it is a little bit like a flashlight.

- Machine for rings. Makes from the workpiece decorative rings of different diameters.

Each of the described tools is responsible for a certain processing of the workpiece. However, to keep them at home all - this means sacrifice free space. Therefore, in recent years, more versatile tools have been widely spread, allowing to work with the metal complex. Almost any of the described tools can be done independently if necessary. Cold forged drawings can be found on the network or acquire from specialists. But you need to remember that to create your own machine you need to have the necessary skills and knowledge.

Note! Not all machines imply exceptionally manual processing. Some of them have electric motors. But even with them, work remains rather complex and exhaustive. Therefore, to acquire a more complex machine with the engine only if you have a large amount of work. If not, it's better to do it hand.

We also draw your attention to the presence of functional industrial machines that allow you to produce almost the entire complex of processing work with the metal. However, for domestic use, such a machine is not the best option, because its cost can reach up to ten thousand dollars, which often turns out to be unjustified if the forging is a hobby, and not your basic work. Nevertheless, work with the machine is easier and more pleasant.

How is a cold forging metal

The key task is regardless of the selected material and the tool - give the workpiece the desired form. You can use various techniques in your work, but they need your own toolkit and processing method. As mentioned, the heating of the metal in this case is not provided, so the differences with hot forging are very large. Now you need to understand, on the basis of what technological techniques you will work.

In general, the whole process can be divided into several main steps:

- creation or choice of a suitable sketch;

- purchase of the desired material and tools;

- directly forging.

Drawings can be created in computer editors, draw from hand or find ready-made online and print. If you have the opportunity to seek help to experienced blacksmiths, you can ask them a couple of simple drawings to practice. They also advise that and how best to do to get the best result. You must understand that without a quality drawing it is not worth working. It will orient you in which items you need and in what quantity. In addition, the drawing in the hands is much easier to calculate the degree of their elasticity and strength. And, naturally, the drawing is easier to collect all the elements obtained in the process in the process in a single integer.

There are several groups of adhesive elements that can be combined with each other. Most of them are essential components of almost any project in our time. Let us dwell on each of them.

- Paws. They may have different shape and size, however, generally are unrolled metal rod plane edge. As a subspecies of the legs there are also peaks - pointed items that can not be flat. They are made with the same technology.

- Curls. Their are several subspecies. Czerwonka - ends are bent in different directions. Because of the similarity of their US dollars are sometimes referred to with the currency symbol. Snail - curl embodiment, when one end of the workpiece is a spiral, and the second in this case remains smooth. The volute both ends are bent in one direction.

- Rings. The machine is installed, and the rod is bent in a spiral. From the resulting spring rings are cut and hammer aligned joints.

- Torsion. Longitudinal twisted kind of the propeller on its own axis. There are many variations of the torsion bars, however, the most original and popular - lanterns and bars for a variety of fences. They are easy to make and look great.

If we consider cold forging detail, there are three Fundamental Technology:

- Extractor hood. It is a process where by reducing the cross section of the preform occurs length increment. The most common type - reeling, with the help of which are above the peaks and legs. For rolling raskatochnye you need to use the machine. It is put an end to the rod and the rolling process begins. Depending on the machine configuration can be obtained with different foot shapes with or without texture. To create a peak above press machine use. It also gives the metal the desired shape and makes the pointed end of the workpiece.

- Twisting. The blank is twisted on its own axis. Basically it uses Twister. With it you can create almost any torsion. One end of the workpiece need to clamp in the grip, and the second scroll to the desired number of revolutions. If you want to create a lantern, then you'll need two or more rods. First, they need to spin on its own axis, and then compressed. In this case, the bars to the sides, and you get a flashlight perfectly flat shape.

- Bending. One of the simplest forms of treatment. Is to simply bending the blank in the right place at a certain angle, you can adjust yourself. Most often used for bending the cochlea. For this, one portion of the preform is fixed in the machine for a particular pattern, after which it can be bent to the desired angle.

So that all the items obtained are collected in a single whole, you will need welding and assembly table. If you do not have welding, you can buy it or take it on the rental. Its cost is rather low. The main thing in the work is to follow safety. In general, the cold forging is most widespread among beginner Kuznetsov and entrepreneurs. For her, no additional knowledge and skills are needed. Only free time and desire to work.

Now and you know how to make a cold forging and create unique metal items to decorate your own home or site. Good luck!

Start a discussion ...

Start a discussion ...