How nice after the working week with her heavy and rich schedule to collect a family and go beyond the city to the cottage. In this place, you can enjoy silence, fresh air and wildlife, which in the kingdom of steel and concrete is practically no left. Own country plot is notable for equipping it we can at our discretion. We ourselves decide where we will have an alpine slide, and where the swing for the defers.

Swing - comfort on the country

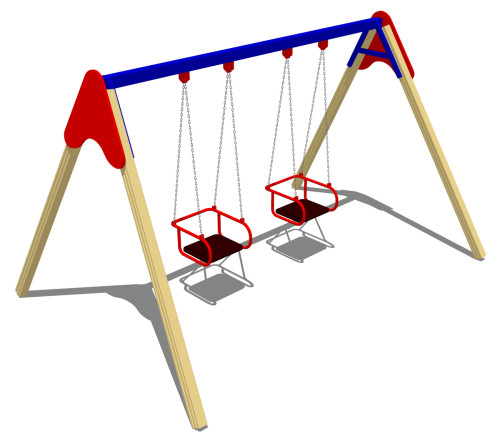

This is one of the indispensable attributes of his own home or country site, especially if you have children. They always like to ride a swing, and adults at this time can do their affairs. Nowadays in building supermarkets, you can find many options for ready-made swings, from simple models that are suspended on the natural support (tree or wall of the garage, etc.) to whole complexes that are integrated into the arbors have a roof, and they can be placed on them. More than two adults man. True, it is worth noting that their cost is quite high, which is not always an acceptable option for the family budget.

There is a way to save money by making the design data with your own hands. The network has a large number of drawings of country swings of various models with step-by-step manufacturer's instructions, so if you are able to distinguish the planer from the tree hacksaw, and the nail from the self-drawing, they can be able to cope with this task. We will tell more about the various variants of the swings and methods of their manufacture.

Simple option - Tire on chains

This is the easiest option of cotton swings with your own hands, which almost all adults, being children, did themselves. Their design requires suspension. Such can perform a massive tree branch, pipe, fixed between the house or garage, or a separate design. For the manufacture of such a swing, we will be needed:

- Old tire (with high profile R19).

- Chains and carbines.

- Ry-bolts M12 (bolts with a special eye, for which the chain can be attached) - 2 or 4 pieces.

We take an old tire, put it horizontally, in the upper part of it we make 4 holes. To do this, you can heat the piece of reinforcement and burn the bolt hole. From the inside to the bolt we wear wide washers and clamp nuts. The tire can be attached vertically. Then we will need only two bolts. Krepim chains for which they suspend the tire to the support. Chains and fasteners should be high quality and strong, because the main thing for children's swings is safety.

Option 2 - Board on the ropes

Made in almost the same way as the first design option. We take a small board with a width of 30 cm and a length of 50 cm. Its thickness is usually at least 30 mm, since it should withstand the weight of even an adult. At the corners of the boards, we send the holes, with a diameter of equal dimensions of the ropes. We produce ropes into the holes, and tie at the ends of the nodes that will keep the board. Next, fasten them on the support.

Option 3 - Production of swing with support

For the manufacture of support, you can use various materials: metal pipes, massive boards or logs. Consider the manufacture of support from the bar. For this we need:

- bar size 100x100 mm,

- fasteners

- cement, sand and water.

Procedure for work:

- First we make design details. In each post, which will hold the crossbar, cut out the groove, resembling the design of the "Lastochka Tail". At the crossbar, we make the protrusion.

- Next under the tables digging the pits. For this you can use icessur.

- Then connect the crossbar and pillars in one design. Connection locations are better to enhance with metal corners.

- After the design is assembled, starting to install it. Do it better together. By installing the supports of the support, align them in terms of the level, fix and fill with concrete. That part of the support that will be underground must be treated with an antiseptic and open mastic.

- After the design is installed, it can be strengthened with a kosnock. To do this, we take the bar and install it at an angle of 45⁰ to the front post and rear.

- Kosinki for similar technology, like pillars, omit under the ground and concrete. These designs will prevent the swing tipping when they are subject to load. Now you can attach any swing on such a support.

Option 4 - Sophisticated swing-shop from metal pipes

Such country swings are quite difficult to make. In order to make all the design details, it is necessary to have metal welding skills and the corresponding equipment. If you have it all, then you can proceed to work.

For the manufacture of the design we will need:

- Steel pipes with a diameter of about 70 mm.

- Metal corner 25x25.

- Two pieces of reinforcement with a diameter of 10 mm.

- Two wooden shields from boards.

- Welding machine, electrodes, angular grinders.

- Repshuur (special climbing rope, which is able to withstand the load of more than 300 kg).

- Fasteners for cord.

Sizes of our swing:

- length - 2.5 m.

- height - 2.5 m.

- length 1.5 m lateral stops.

For these dimensions make drawings of country swing their own hands.

Order of works:

- We begin preparation of materials. Grinder cut tube. For the longitudinal base, and the beam size of the pipe segments is equal to 2.5 m, the transverse base - 1.5 m, for inclined crossbar stops - 2.61 m.

- The first thing weld base. The pipe ends are cut off at an angle foundation 45⁰ and chamfer. Then fix them.

- Further welded to the corners of the base-support triangle. Before final welding expose their level.

- Then welded crossbar. It welds eyes of bent rebar, which will be suspended for the swing. All metal gruntuem and color paint.

- We turn to the production of seats for swings. To do this, we weld 2 of the rectangle from the corner. Their ends are cut at an angle grinder 45⁰ and anchoring welded together. Rectangle-seat, the size of 2 x 1 m., And back to the dimensions of 2 x 1.2 m. Weld angle 100⁰.

- We proceed to the construction of structures next step swing set wooden boards on the base of the bracket. Panels fixed thereto by means of screws or bolts. On the back end, and the seat of the welds reinforcement fixing lugs cord.

- Dangle a swing at Repshnur. To do this, fasten the cord to the lugs on the seat and backrest. In the middle of the cord fix 2 carbine.

- That the cord does not slide on the carbine, at fixed locations stifle its collar.

In order to swing was more comfortable to sit on the back seat and fasten sheets of foam and then skin-tight back and seat with a thick cloth. Here are our swings and ready. Their size allows even an adult to lie comfortably in the open air, and the design can withstand up to 3 adults. If time permits and the materials can be installed over a small canopy swings, whereby time on them, even in rainy weather can be carried out. To this end, the crossbar weld two guide tubes of smaller diameter, between which the pull special waterproof material used for the manufacture of awnings and tents.

Whatever the design of the swing, from the simplest to challenging, they will be able to deliver you and your children a great pleasure. The most important thing in the manufacture of swing for giving with your own hands is to do a design with a three-time storage margin, because safety is above all. After you finish work, make a photo of country swings, and share it with others.

Imagine some other options for giving to your attention:

Start a discussion ...

Start a discussion ...