Warming just a rebuilt house from a tree is much easier than to make such work in an old wooden house, which is fully equipped. If you only built a house, it is best not to rush to the finish and correctly insulate each living room. These work begins with the ceiling, but not always owners of houses know what materials it is worth stocking, so that there is more heat in the cold season in the cold season. Our task is to tell about what you can warm the wooden ceiling.

Why do you need to warm the ceilings?

Many of the newly minted masters, once rebuilt the house from a tree, consider that this environmentally friendly material and so has a good thermal insulation properties and extra insulated ceiling is not required. Many of the approaches is not responsible to the warming of the wooden ceiling, and in vain, because a large percentage of the heat is goes through the ceiling into the street, especially in winter. For example, during the cold season to warm up and to keep the heat in a wooden house, it is necessary to exert maximum effort. Accumulated in the indoor heat rises (a natural circulation of air), and if the ceiling is not protected, the warm air will go out. Especially lost heat in areas such as kitchen and bathroom. Therefore, if to solve this problem, the savings can amount to 30% of the heating season.

It is important to take into account such things, that if the house is new, then proceed to the insulation of the ceiling in a wooden house can be no earlier than a year after construction, and only in summer. Then we can talk about the proper insulation of the structure and economy.

The better insulate wooden ceiling

The construction market offers us a wide range of insulating materials. Each of them is worthy of attention, but not always it can be suitable for insulation of ceilings in wood.

Let's consider the basic insulation that can be used to retain heat in wooden houses:

- environmental wool (ecowool) - breathable material well fills all gaps and voids. Prevents blowing wooden ceilings and is moisture inside. Also protects the material from mold and mildew. Insulation is made from natural materials and recycled paper. The material is applied to the surface or blown by means of special settings, so do yourself ecowool installation impossible without special expensive equipment;

- glasswater is a popular insulating material that is widely used in construction for the insulation of buildings and structures. If you have chosen glass gamble, then it should be borne in mind that the glass gamble passes moisture (a small amount), so when the wooden ceiling is insulation, it is necessary to take care of organizing the insulation of the room. If this moment is not respected, the thermal insulation properties of the material will be violated. Glasswater comes in plates or rolls. The material does not burn, has sound insulation properties. Among the minuses of this insulation is a knife when working, so you need to immediately think about a special working form and the fragility of the material. After the ceiling insulation, it is necessary to throw away everything from the mask and gloves and ending with work clothes. Get rid of the smallest particles of fiberglass will not succeed. Builders recommend using fiberglass for the insulation of the ceilings in residential individual homes - lay the plates on the semi attack, provided that this room will not be actively used;

- minvata is an easy non-flammable material that is allowed to use wood houses for insulation. Among the disadvantages can be noted only one - in the production of insulation, formaldehyde resins are used. If you choose a cheapest version of the insulation, then toxic substances will be present. If the insulation color has a characteristic yellow color, it means that resins are present in the fibers. It is allowed to install the inner surface of the ceiling of the Light yellow shade of the minevat. A cheap insulation with dark fiber is better not to use;

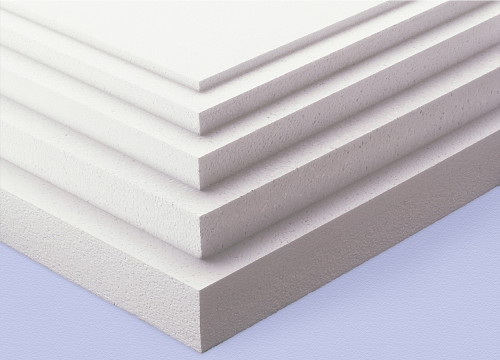

- the polystyrene foam plates are a popular insulation, which is widely used to label wooden ceilings and walls. Attracts accessible price and simplicity of installation. The advantages of this thermal insulation material is that the polystyrene is has a small weight, easily mounted, retains heat. The usual foam cannot be used for the insulation of the ceilings from the tree, since the material is very fragile and will not "breathe";

- bulk materials - it can be ordinary sawdusts (they can fall asleep the floor in the attic), ceramzite, perlite, slag, etc. The lightweight material is well holding heat, it has soundproof properties, it does not burn and environmentally friendly. Among the backs of such materials for the insulation of wooden ceilings were marked with a flowability (over time it is necessary to add insulation) and the possibility of installation only on one side - from the attic;

- vegetable materials can be vegetable batting, flax fiber mats or straw. They are distinguished by hypoallergenia, environmental friendliness, ease of installation. Cons of vegetable insulation - low thermal insulation, flammable materials, does not have sound insulation properties, besides, such raw materials will be bait for rodents and insects;

- mixtures of cement with sand, sand clay with the addition of sawdust, crumbs of foam, clay (any light bulk component). The mixture for the insulation of a wooden ceiling can be made or purchased the insulation in the store. Cons of such a material - when insulation, the attic may occur, since it is impossible to put a large layer of insulation. If you use such a mixture for the insulation of wooden ceilings, then in the attic you can equip a living room or make a workshop.

Wood ceiling insulation methods

There are 2 methods of laying insulation:

- The ceiling is insulated outside.

- The ceiling is muted by insulation from the inside.

Consider both options for maintaining heat in houses with wooden ceilings.

How to insulate a wooden house ceiling

It is possible to obtain a greater percentage of heat conservation only by insulation of the ceiling outside, that is, if you put a layer of material into an attic floor. Warming technology remains unchanged. First you need to remove all the materials on the floor of the attic to get to the "rough" floor covering. Then the surface is thoroughly cleaned from garbage, dirt and dust. If there are damaged areas (the tree rotted, spoiled by rodents), they need to be repaired, that is, change the poor wooden coating to the new one. Then you need to handle the draft wooden floor in the attic antiseptic to protect the tree from the penetration of moisture, mold and attack rodents. Next, the installation itself is performed by the installation of the selected insulation, during which special attention is paid to the close of cracks and holes in the floor. After that, the waterproofing layer is stacked on top of the insulation. If the room in the attic will not be actively used, then at this stage of the work you can stay. If it is planned to put the room under the workshop or residential premises, then it is necessary to put the chipboard or DVP plates on the layer of insulating material, and then you think about how the floor can be in the attic (ceramic tile, linoleum, laminate, etc.).

If a bulk material is used as a heater, and the attic room will not be operated, then the insulation can be left and not to cover the waterproofing film. After a while you have to plug or replace part of the insulation. For example, if you find that sawdust starts to mold, then this site needs to be completely updated. When the waterproofing is not laid on top, this part of the work will be made much easier. This concerns only sawdust, the remaining bulk materials are absolutely hydrophobic, that is, if moisture falls on them, they repel it.

If you insulated the floor in the attic of the foam, then it is necessary on top to put a layer of waterproofing so that the insulation does not destroy the outdoors. From above, you can mount plywood sheets, boards to keep the thin coating from mechanical damage.

With the outer insulation of the ceiling, it is important to first put the insulation around the chimney and other communication structures, and then fill the remaining surface.

Warming of wooden ceilings from the inside

This method is not much different from the outer method of insulation (the exception is the use of bulk materials). First, the layer of waterproof canvas is placed, then the insulation is placed and then the insulation layer. To improve the external quality of the ceiling, it is fed by any selected material: plywood, waf or chipboard, plasterboard. Also hobs the layer of the insulation of the stretch ceiling or the suspension system. Materials can be attached to the fastening element or glue composition. Thin rails are used as insurance or durable kapron cord.

An important point - before proceeding to the insulation of wooden ceilings, it is necessary to predetermine where communication lines (Internet, electricity) will be laid.

What to take into account when working

It is impossible to just take and proceed to the warming of a wooden ceiling. You must first consider everything to the smallest details, make a estimate or write a detailed action plan. So you can really appreciate your capabilities and not spend money on unnecessary materials. Having a estimate, you can calculate the desired amount of materials, taking into account their physical properties. For example, if you plan to install foam plastic, then it is necessary to take into account that foam for mounting at least moisture-resistant, but under the influence of direct sunlight can quickly collapse. Therefore, it is important to think about how such sites can be closed. In addition, if you gathered to lay the insulation from the wool, which will "breathe", then it is necessary to properly choose the hydraulic or vapor barrier material.

Buying building materials, do not be lazy to read the information placed on the package. If you saw the inscription "only for the ceiling", then such a insulation will no longer be suitable for outdoor insulation (the floor in the attic).

When you stock all necessary, it is better to buy fasteners and primer with a small margin, and in the store, agree that you have taken the remnants of building materials. This practice is welcomed in small construction stores or in the building materials market.

Since our goal is a qualitative insulation of the ceiling of wood, and therefore the maintenance of heat, then do not try to speed up the course of work and acquire cheap materials. For example, if instead of a special film buy ordinary polyethylene, then all your efforts will be in vain. After a few years, you will have to warp the ceilings. With a competent approach, it is possible to maintain heat in the house 10 years ahead.

How to warm the wooden ceiling

Consider the popular method of insulation of a tree ceiling with a roll insulation. It can be miniwall or glass gamble.

The sequence of work is as follows:

- Drive nails on the draft ceiling, just not in the usual way, and so that the hat is a little speaking. It is necessary to tighten the thread zigzago.

- Next, you can lay a layer of insulation. It is easier to work together - one person will lay the material, the second - pull the thread. Next, you will need to pave the insulation between the thread and the ceiling.

- After performing this stage of work to the ceiling, attach the film, which will prevent the formation of condensate. Nails can be clogged in the usual way, so that the insulation of the layer is well pressed.

- The latter comes a turn of installation of plasterboard, plywood or any other decorative material.

In the process of work, make sure that the insulation is put tightly and there was no space through which the heat can go out and condensate.

Start a discussion ...

Start a discussion ...